Introduction

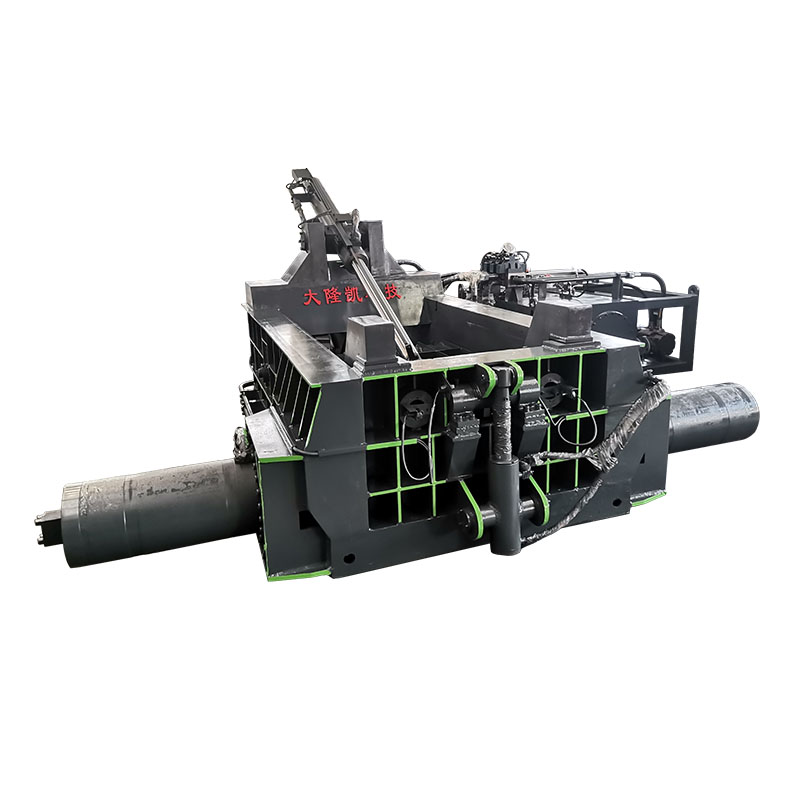

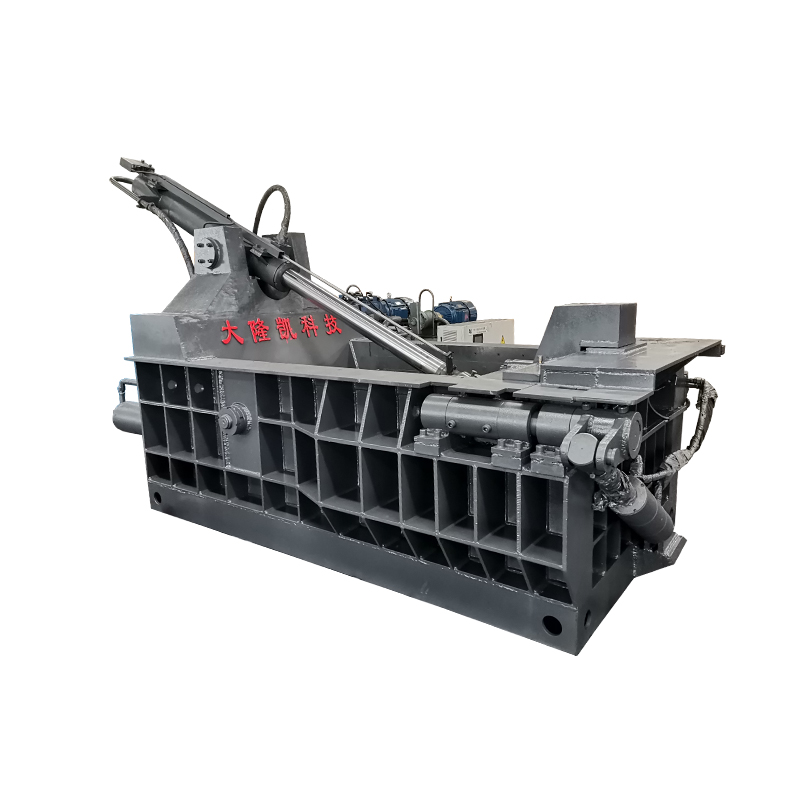

The 200-ton small hydraulic metal baler is suitable for scrap metal recycling processing plants, steel mills, ferrous metal smelting industries, etc. This baler equipment can press aluminum cans, scrap copper, scrap iron, scrap stainless steel, scrap aluminum and other scrap metals.The pressure of the main cylinder of the equipment is 2000 KN, and the size of the material box is: 1800*1400*800 mm. The size of the compression chamber and the shape and size of the block can be customized according to user requirements.

Technical Specification

|

1 |

Main oil cylinder |

Model |

YG320/220 |

Qty. |

2pc |

|

Normal force |

2000KN |

Stroke |

570mm |

||

|

2 |

Side pressure cylinder |

Model |

YG220/160 |

Qty. |

2pc |

|

Normal force |

1000kN*2 |

Stroke |

1650mm |

||

|

3 |

Turning bag cylinder |

Model |

YG180/120 |

Qty. |

1pc |

|

Normal force |

650kN |

Stroke |

1520mm |

||

|

4 |

Door cover cylinder |

Model |

YG125/80 |

Qty. |

1pc |

|

Normal force |

95kN |

Stroke |

275mm |

||

|

5 |

Size of feed box |

1800*1400*800 mm |

|||

|

6 |

Size of bale |

300 mm Octagon |

|||

Machine Detail

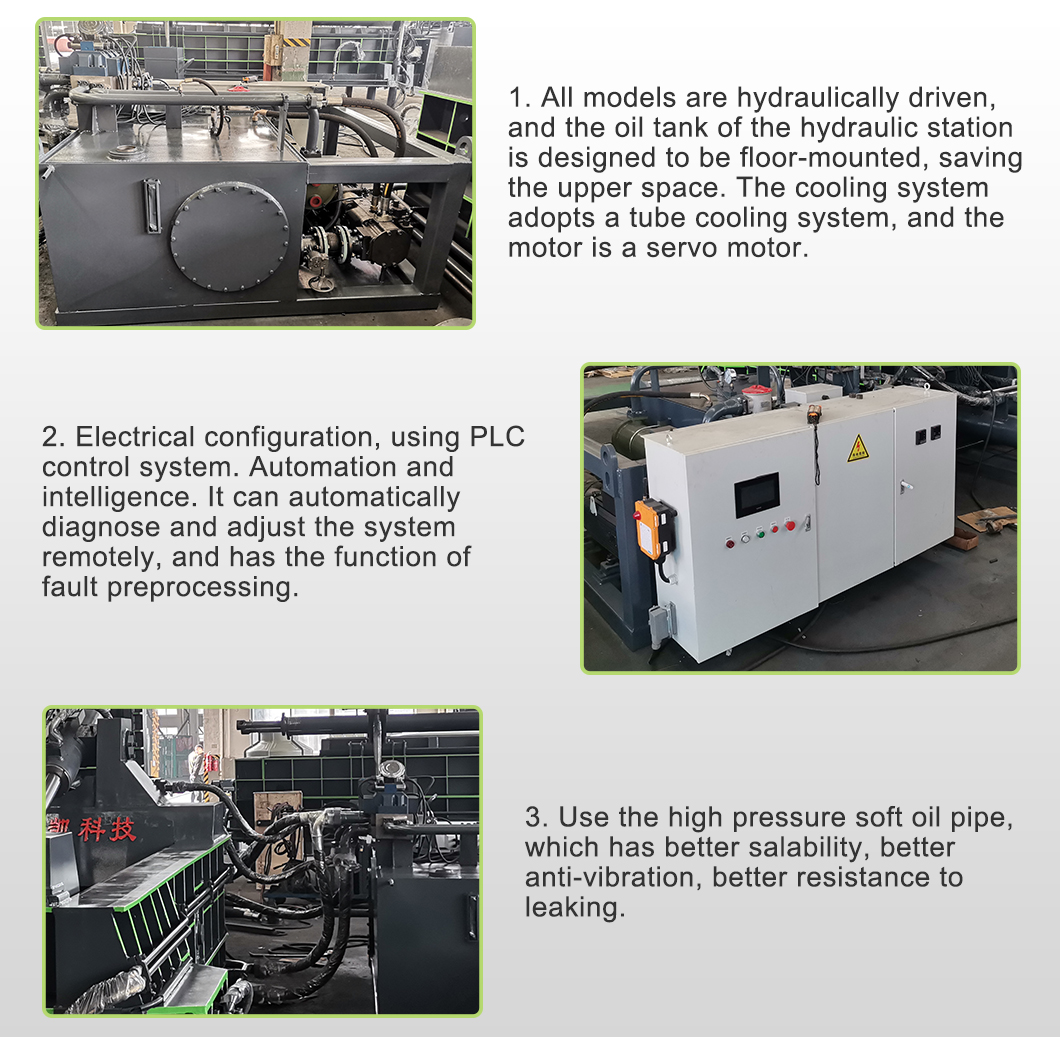

1. All models are hydraulically driven, and the oil tank of the hydraulic station is designed to be floor-mounted, saving the upper space. The cooling system adopts a tube cooling system, and the motor is a servo motor.

2. Electrical configuration, using PLC control system. Automation and intelligence. It can automatically diagnose and adjust the system remotely, and has the function of fault preprocessing.

3. Use the high pressure soft oil pipe,which has better salability, better anti-vibration, better resistance to leaking.

Related Products

Are there any products you like?

24 hours a day online service, let you satisfaction is our pursuit.