Introduction of the baler

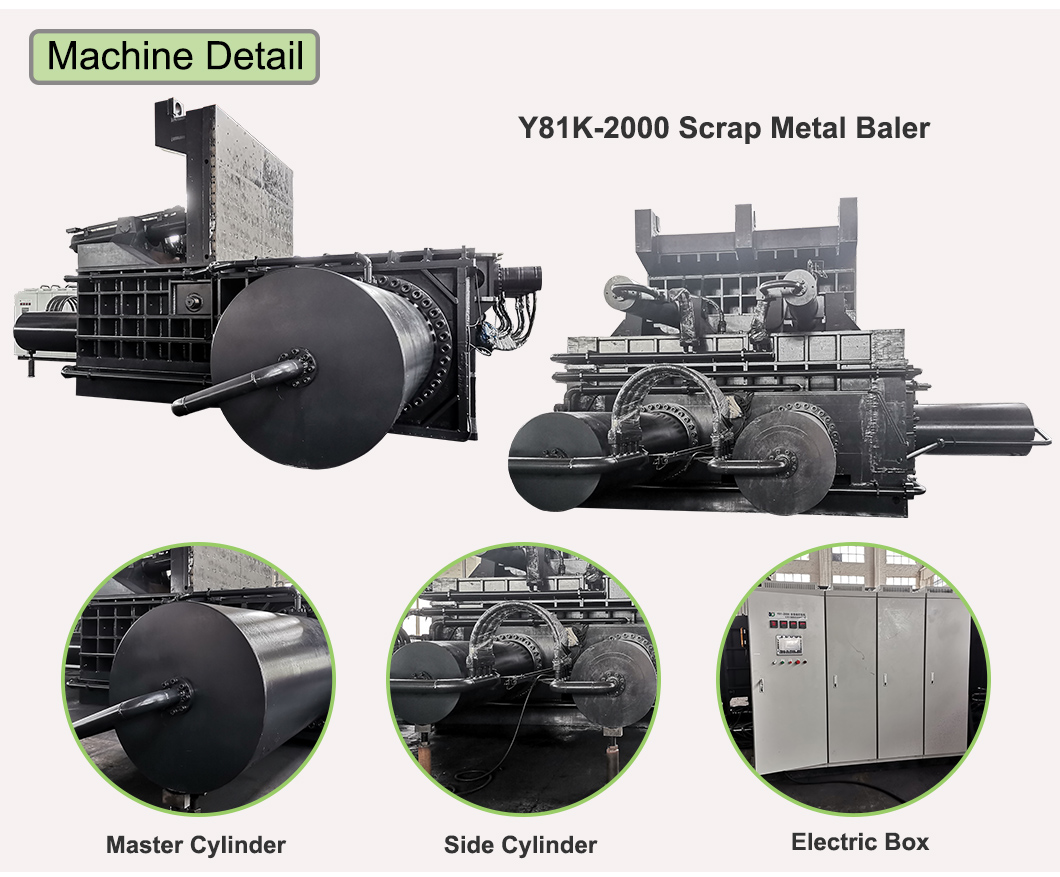

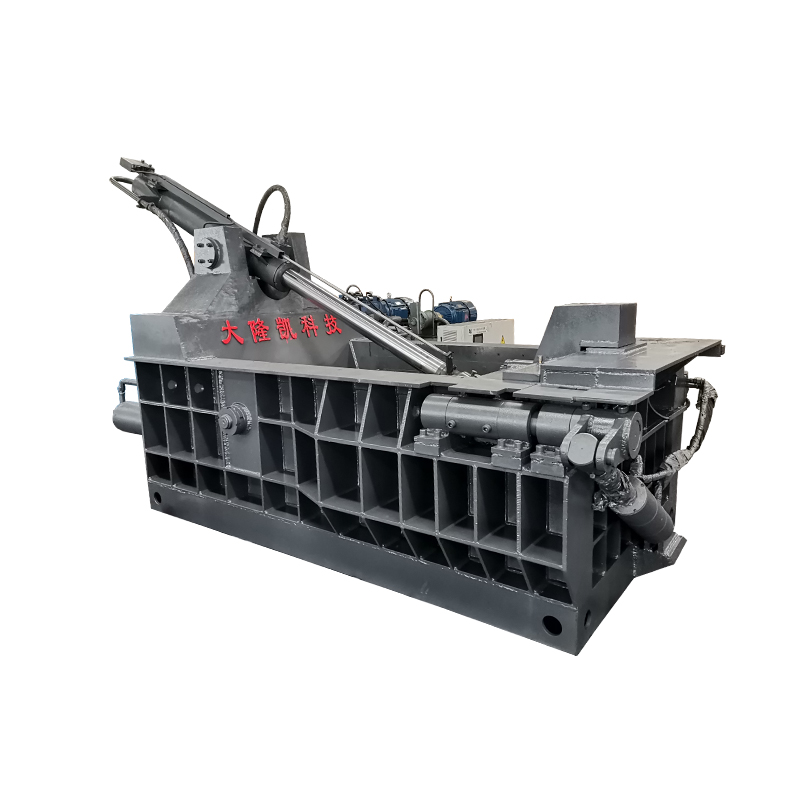

Our Y81 series hydraulic metal balers have been widely used in the scrap metal recycling industry. The Y81 series metal balers are made of strong materials, and the accessories are all well-known brands at home and abroad, and the quality is guaranteed. This Y81 series 2000-ton baler adopts an external door cover lock cylinder, which can more firmly fix the door cover after the machine is started. The two sides of the door cover are equipped with blades, which can cut the scrap metal beyond the material box, so that the baler can better complete the baling process. There are three ways to operate the machine. The first is to operate the touch screen on the electrical cabinet; the second is to remotely control the baler through the remote control; the third is to be equipped with a manual console to control the operation of the baler ( can be selected according to customer needs). For more machine configurations, we can customize production according to customer needs.

Technical Parameters

|

NO. |

Parameter name and content |

|

|

1 |

hydraulic system working pressure | ≤25MPa |

|

2 |

Press box size | 3500x3000×1500mm |

|

3 |

Block section size | (700x700)mm |

|

4 |

Bale density (steel) | ≤2800/m³ |

|

5 |

Single no-load cycle time | About 100 seconds |

|

6 |

Operation method | Hand-in-one, remote control operation |

The parameters in the above table are for reference only.

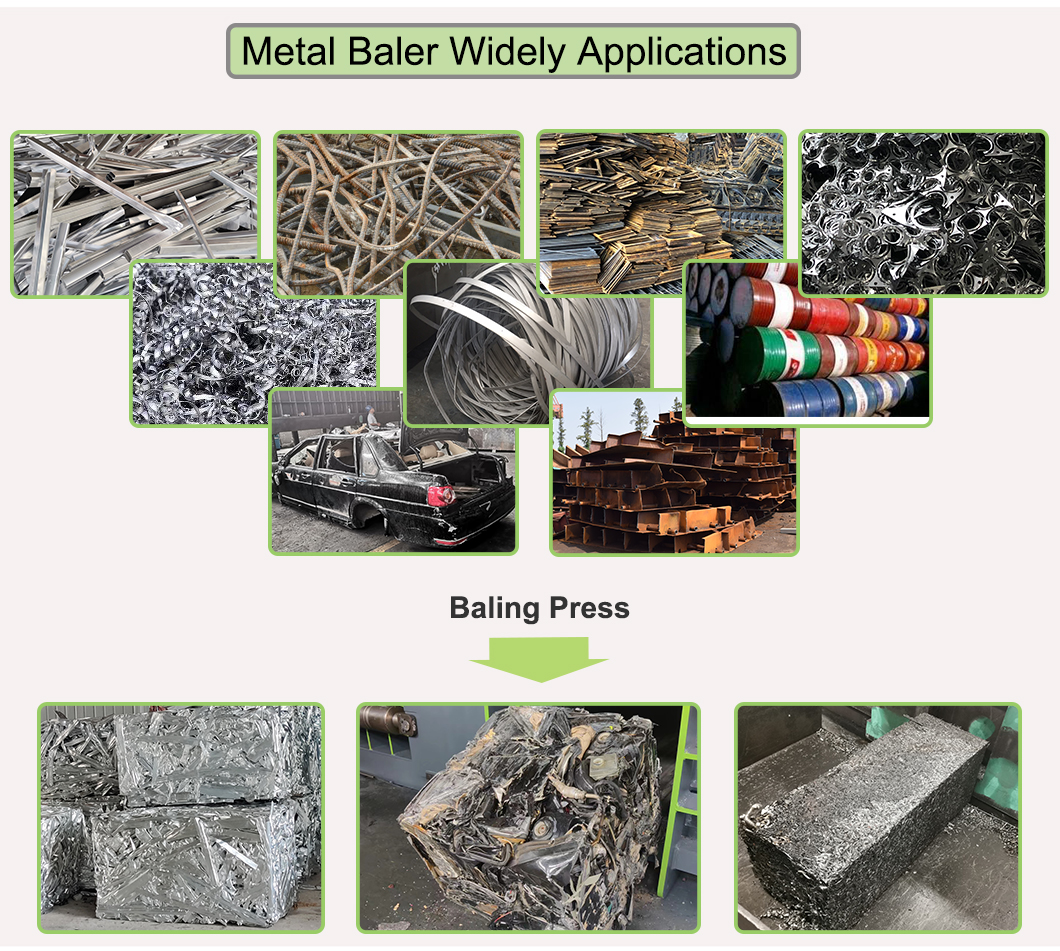

Application

The scrap metal baler can pack scraps into: scrap metal scraps (scrap steel, scrap iron, scrap aluminum, scrap copper, scrap stainless steel, steel shavings), waste oil drums, waste washing machine shells and scrap car frames, etc. The packed waste bales can be rectangular, cylindrical and octagonal. This Y81 series metal baler is suitable for steel mills, scrap steel recycling industries, and non-ferrous and ferrous metal smelting industries.

Related Products

Are there any products you like?

24 hours a day online service, let you satisfaction is our pursuit.