Production Description

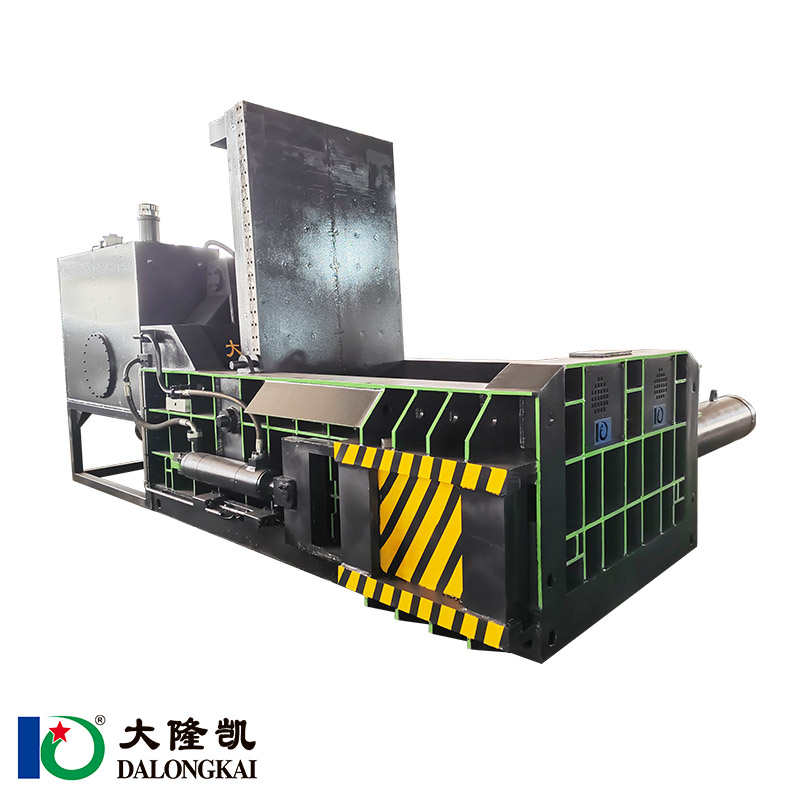

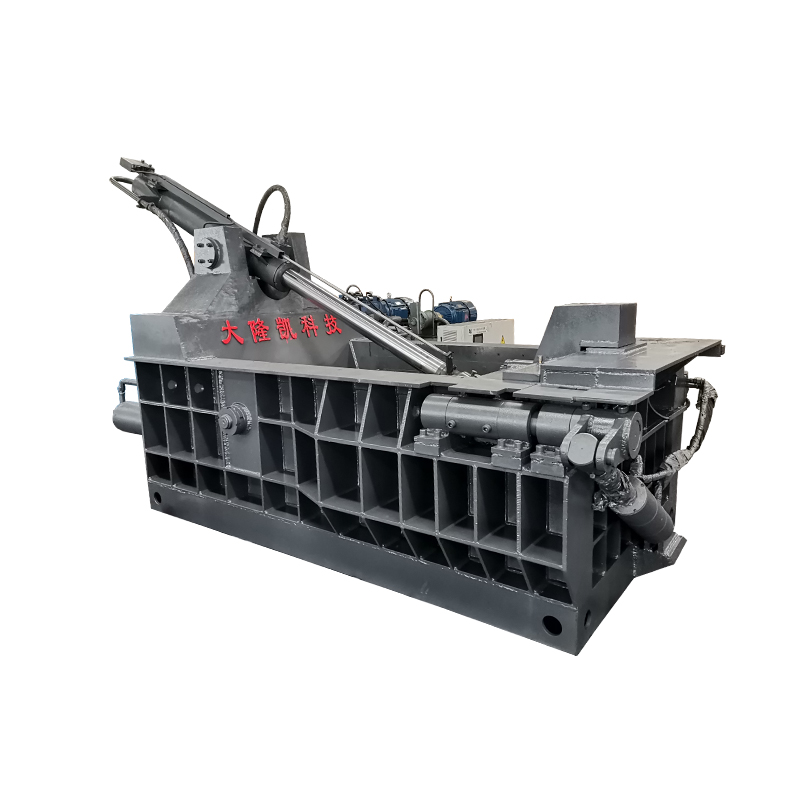

Introducing our Y81 series side discharge 250 ton single master cylinder scrap metal baler, the perfect solution for metal recycling. This baler is designed to efficiently compact metal scrap, specifically aluminum, into dense bales for easy storage, transportation, and recycling.

The main engine of this baler consists of a single master cylinder, two side cylinders, door cover cylinders, door cover, and pressing box. The hydraulic station includes a fuel tank, motor, cooler, and integrated valve block, ensuring smooth and reliable operation.

With a compact and robust design, our baler is capable of handling large volumes of metal scrap, reducing storage space and transportation costs. The powerful hydraulic system exerts high pressure to compress the scrap, resulting in tightly packed bales that are easy to handle.

Technical Parameters

| NO. | Parameter name and content | |

| 1 | hydraulic system working pressure | ≤26MPa |

| 2 | Press box size | 2000x1400x900mm |

| 3 | Block section size | (500×500)mm |

| 4 | Bale density (steel) | ≤2200/m³ |

| 5 | Single no-load cycle time | About 90 seconds |

| 6 | Operation method | Hand-in-one, remote control operation |

| 7 | Productivity | About 7-15 bales/hour |

| 8 | Power Specifications | 380V/3P 50Hz |

Related Products

Are there any products you like?

24 hours a day online service, let you satisfaction is our pursuit.