Product Description

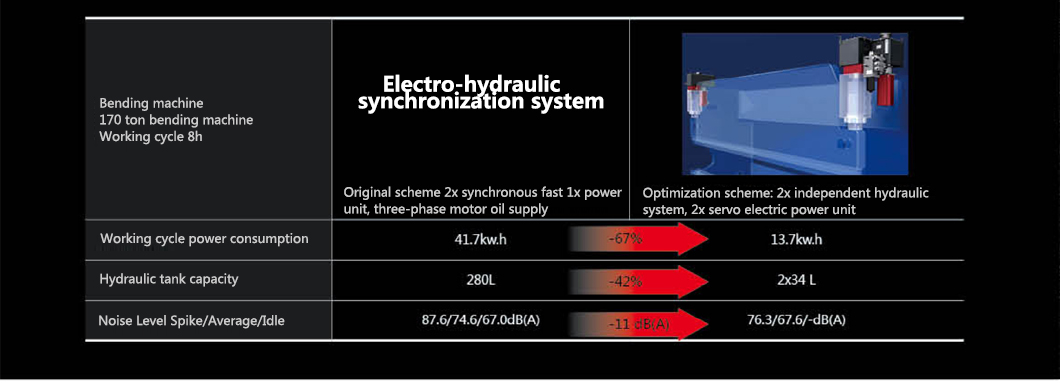

Oil-electric hybrid CNC press brake: The computer controls the flow and pressure of the Y1 and Y2 oil cylinders through two sets of servo bidirectional pump systems, respectively, and directly drives the oil in the upper chamber of the oil cylinder into the lower chamber of the oil cylinder through the oil pump to realize the lifting of the upper die; Turn the oil in the lower chamber of the oil cylinder directly into the upper chamber of the oil cylinder to realize sheet metal bending. The synchronization of the left and right sides of the upper die of the machine tool is controlled by two sets of servo bidirectional pumps respectively. The machine tool not only has high precision, energy saving, low noise, but also is more stable and reliable, with less oil consumption, which is conducive to the manufacture of large-stroke and ultra-high-speed press brake.

Features of the CNC press brake

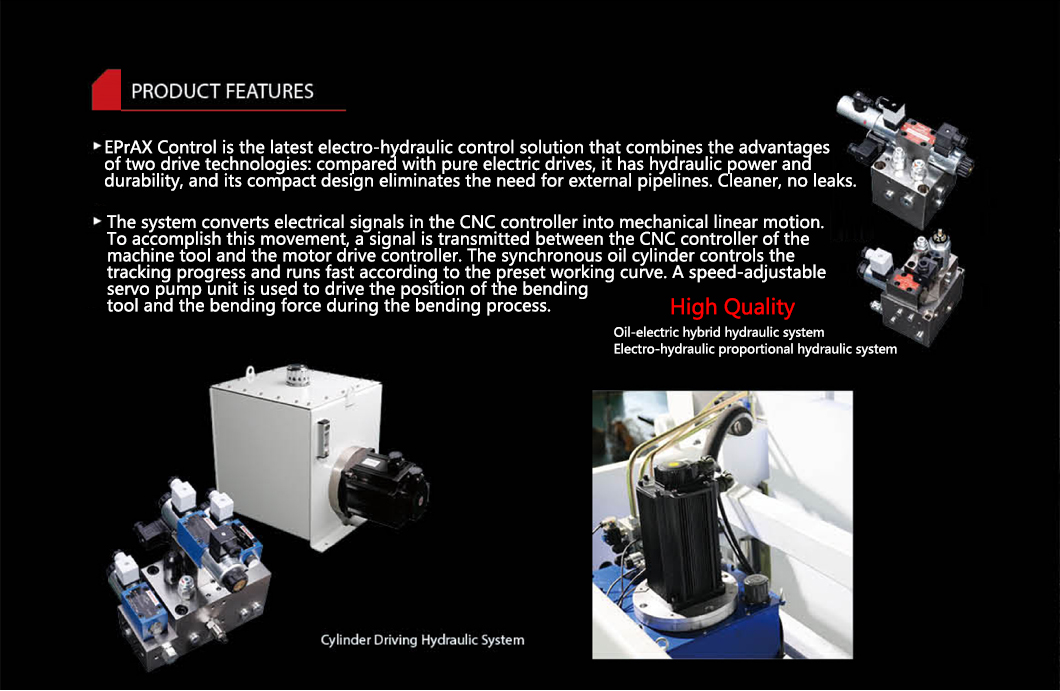

1.EPrAX Control is the latest electro-hydraulic control solution that combines the advantages of two drive technologies: compared with pure electric drives, it has hydraulic power and durability, and its compact design eliminates the need for external pipelines. Cleaner, no leaks.

2.The system converts electrical signals in the CNC controller into mechanical linear motion. To accomplish this movement, a signal is transmitted between the CNC controller of the machine tool and the motor drive controller. The synchronous oil cylinder controls the tracking progress and runs fast according to the preset working curve. A speed-adjustable servo pump unit is used to drive the position of the bending tool and the bending force during the bending process.

Machine Detail

Our bending machine accessories are all well-known brands at home and abroad, with guaranteed quality and long service life.

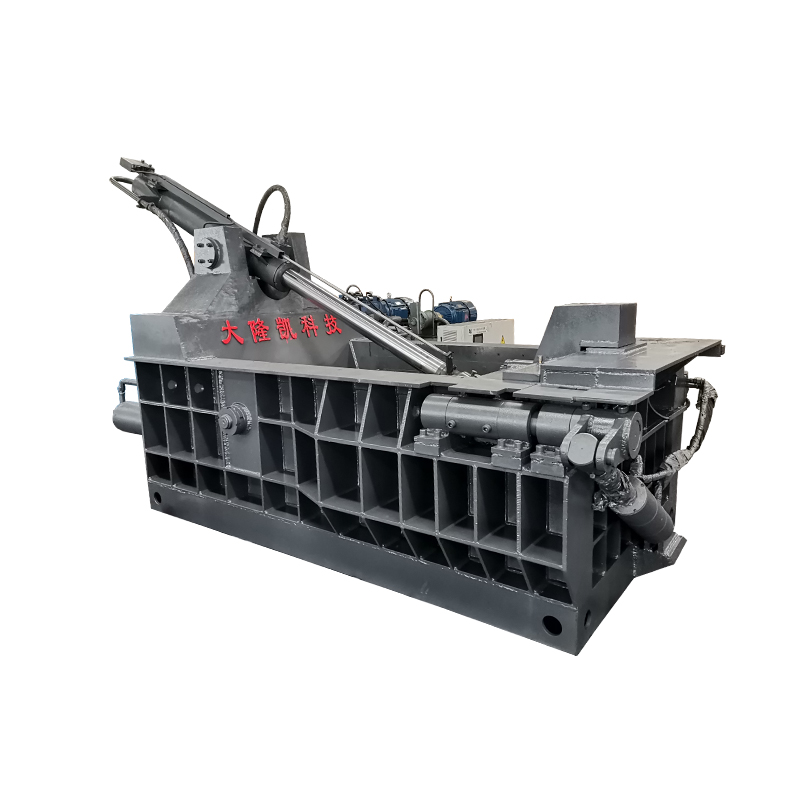

Related Products

Are there any products you like?

24 hours a day online service, let you satisfaction is our pursuit.