Container Shear

-

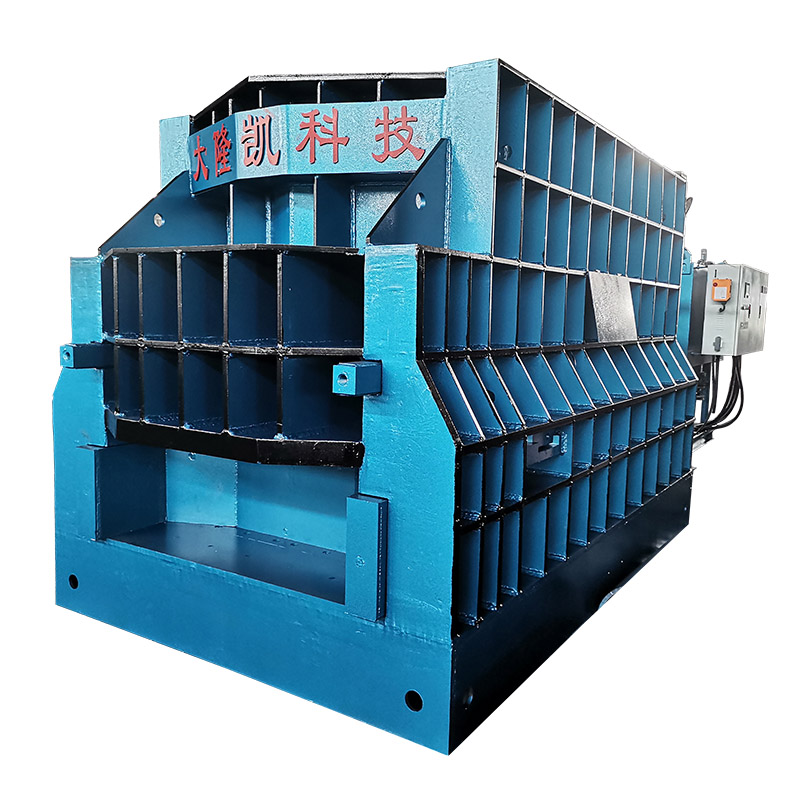

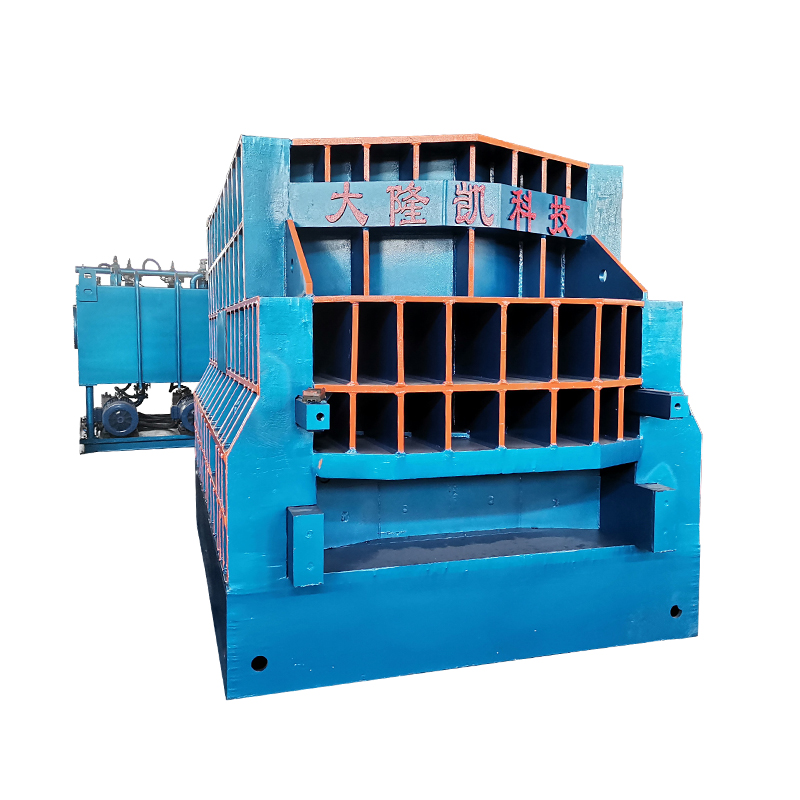

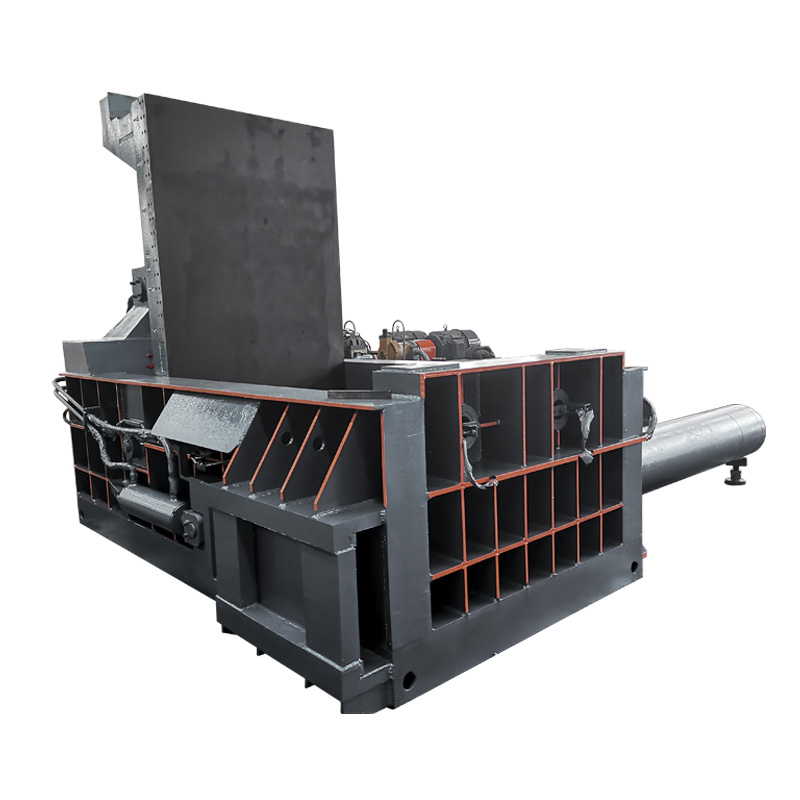

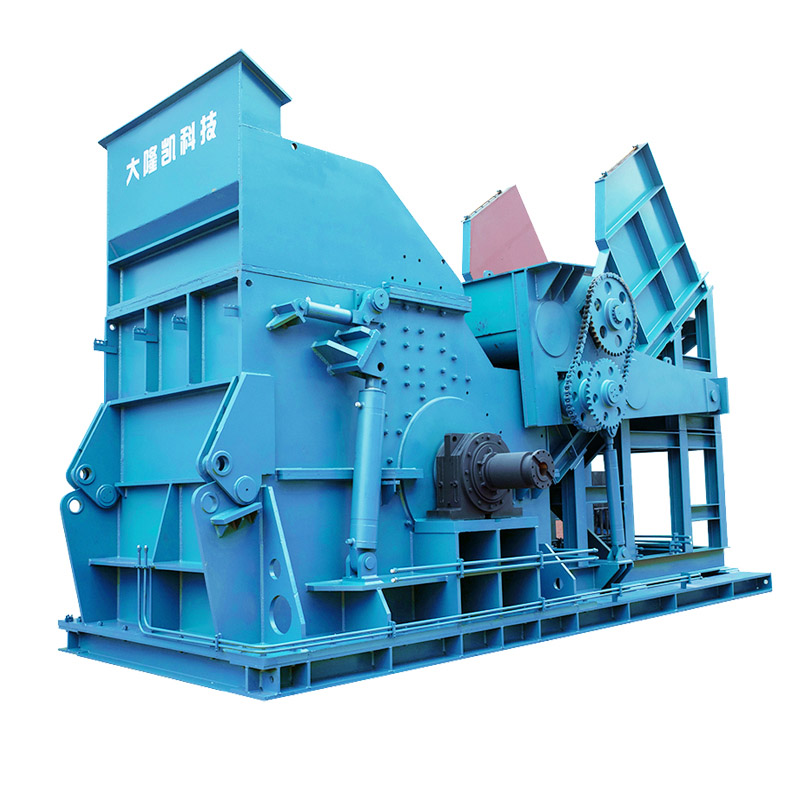

Horizontal Hydraulic Scrap Metal Container Shear

Product Description The box shear is an efficient scrap processing equipment. The box-type shearing machine has a compact structure and an integrated design that is easy to move. It can be controlled by a hybrid engine and a motor, or can be controlled separately by an engine or a motor. The biggest advantage of box shear is its high overall utilization rate. Technical Parameters Model Max.Cutting Force(ton) Blade Length(mm) Shear Height(mm) Production Rate(t/h) Power(kw) WS... -

WS-630 Container Shear Scrap Metal Shearing Machine

Introduction of the container shear WS series horizontal fully automatic box shearing machine is a machine used to cut or shear metal scrap into smaller pieces. This box shear is commonly used in metal recycling facilities and scrap yards to process metal scrap. Metal scrap box shears are essential equipment in the metal recycling industry as they help reduce the volume of metal scrap, making it easier to handle and transport. Technical Parameters NO. Parameters And Content 1 Model WS-... -

Scrap Metal Container Shear Metal Cutting Machine

Introduction of scrap metal shear WS series horizontal container shears are suitable for large steel and non-ferrous enterprises, circular economy industrial parks, national urban mining demonstration bases, scrap steel processing and distribution centers, scrap car dismantling and remanufacturing plants and branch plants or temporary scrap yards, etc. The main function of this scrap metal shear is scrap metal cutting and processing. Technical Parameters 1 Shearing cylinder Model Y... -

800 Ton PLC Control Automatic HMS Container Shear Cutting Machine

Product Description WS series container shearing machine is suitable for steel ingots, steel blanks and parts of heavy machinery for cutting heads and tails, various steels and their cutting heads, trimming ship plates, various machine scraps, rails, train wheels, and other agricultural machinery, steel furniture, etc. Small scrap steel such as utensils and tools. The WS shearing machine has low operating cost, high efficiency, no pre-compression cap, less operation, and continuous feeding. T... -

WS-630 Hydraulic Heavy Scrap Metal Shear Machine OEM ODM

Product Description This horizontal metal shear is applicable for cutting the metal shaped in different cross section like round, square, channel, angle, I shape, plate and various waste structural metal at cold state. It brings convenience to the baling, storage and transportation of scrap metal materials, also offers qualified furnace charge for smelting plant. With large application range, this machine is commonly used as the processing equipment in the metal recycling unit, casting room o... -

630T Heavy Hydraulic Waste Section steel Box Shear

Box shear is a kind of scrap steel processing equipment. The designer of the box shear comes from Europe. It has a compact structure and a one-piece design for easy movement. It can be controlled by a hybrid of an engine and an electric motor, or can be controlled by an engine or an electric motor alone.

-

Hydraulic Scrap Car Shell Non-Ferrous Metal Steel Container Shears WS-630

The hydraulic shearing machine has a compact structure, and the body is welded with steel plates into a box-shaped structure, and its mechanical performance is stable. The shear cylinder is connected by a ball hinge, which improves the stability and life of the oil cylinder, adds a front plate guide device, and improves the force condition of the whole machine. It adopts electro-hydraulic control and is easy to operate. It can realize inching and interlocking automatic circulation. It is one of the ideal equipment for the metal recycling industry and the casting shop’s charge processing. The hydraulic shearing machine is suitable for metal recycling processing plants, scrap car dismantling plants, smelting and casting industries. It cuts various section steels and metal structural parts in a cold state and processes them into qualified charge.

-

WS-800 Scrap Metal Container Shearing Machine

WS series container shearing machine is suitable for steel ingots, steel blanks and parts of heavy machinery for cutting heads and tails, various steels and their cutting heads, trimming ship plates, various machine scraps, rails, train wheels, and other agricultural machinery, steel furniture, etc. Small scrap steel such as utensils and tools.

-

WS-630 Scrap Metal Hydraulic Box Shear For Recycling Industry

Box shearing machine is a new type of shearing equipment for efficiently processing bulk steel and metal scrap. The box-type shearing machine saves a lot of labor costs while closing the cutting and completely avoiding the danger of manual operation, increasing the production efficiency by 10 times, ensuring that the scrap can be quickly recycled and processed to meet the requirements of the refined material into the furnace, and with Comes with a series of benefits such as energy saving, environmental protection and economy.

-

Full Automatic PLC Control Heavy Scrap Metal Container shearing Machine

Container Box shears have a wide range of applications and are mostly used in the scrap metal recycling industry. Box shearing machine can cut all kinds of thin and light materials, metal structural parts and scrap steel of daily necessities. The hydraulic system is mainly composed of pump station, valve station, fuel tank, hydraulic pipeline, etc. The pipeline is welded with imported steel plate, so it is more convenient and quick to maintain and clean the fuel tank. The steel pipe adopts seamless high-pressure oil pipe, which can last longer.

-

WS Mobile Integrated Box Type Scrap Metal Shearing Machine

WS series horizontal automatic shearing machine is suitable for metallurgy, steel mills, scrap metal recycling, renewable resources and other industries. WS metal shears can cut all kinds of light and thin materials, metal structural parts and domestic scrap steel. The integrated horizontal shears can be moved and can be equipped with diesel generators for normal use in places where there is no power supply.

-

WS Series Horizontal Automatic Shearing Machine

This horizontal container shearing machine is suitable for cutting metals with different cross-sectional shapes, such as round, square, trough, angle, I-shaped, plate and various cold-state waste and old structural metals. It brings convenience to the packaging, storage and transportation of scrap metal materials, and also provides qualified charge for smelters. This machine has a wide range of applications, and is often used in metal recovery devices, factory foundries and processing equipment in the machinery manufacturing industry.

Recommended Products

Our machines are mainly suitable for scrapyards, steel mills, scrap recycling processing industry, and nonferrous & ferrous smelting industry.Are there any products you like?

24 hours a day online service, let you satisfaction is our pursuit.