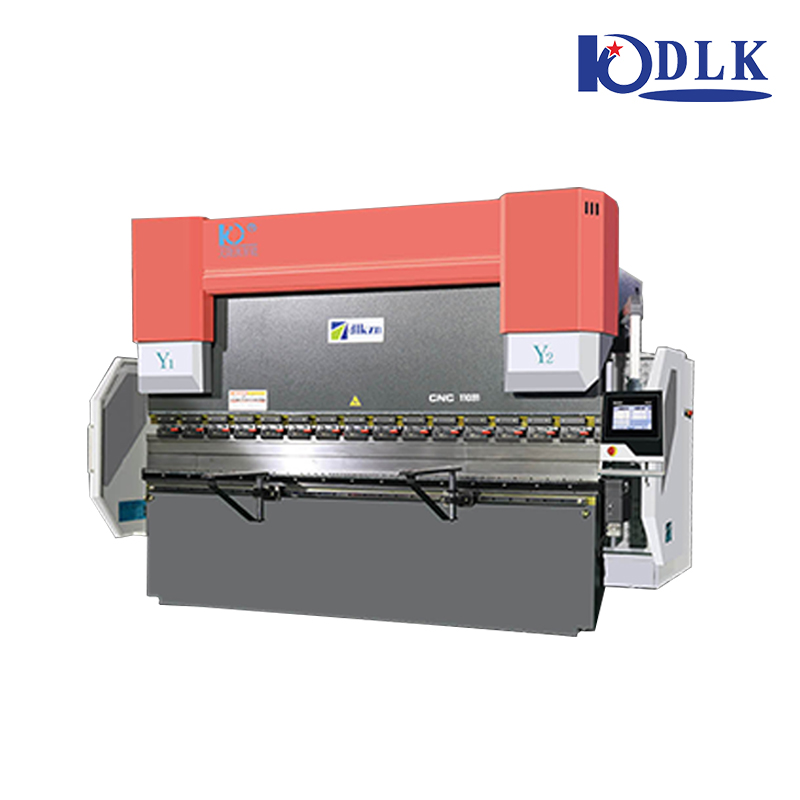

Product Description

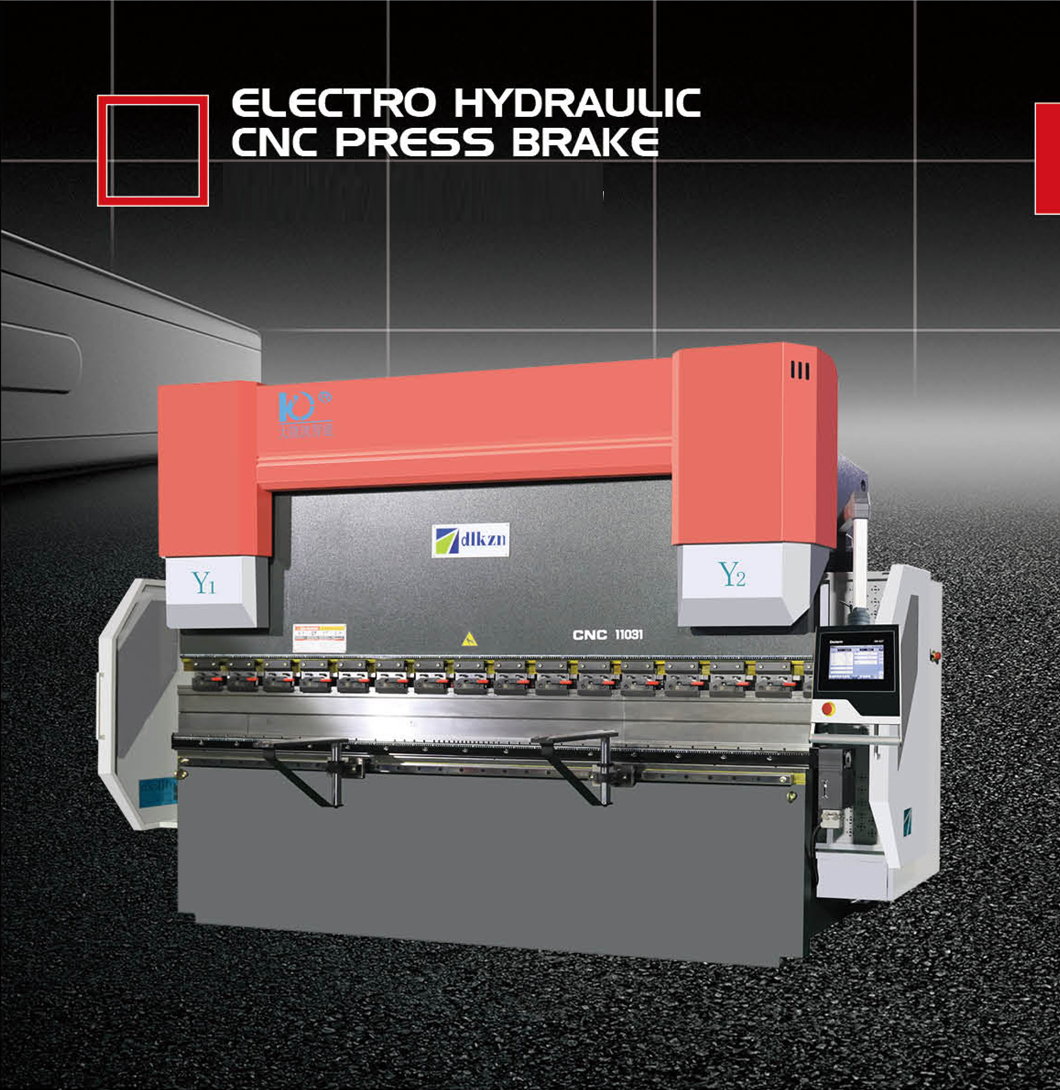

Electro hydraulic servo CNC bending machine(CNC Press Brake) must use electro hydraulic synchronization technology, cooperate with proportional valve, grating ruler, etc., and servo-controlled back gauge is a high-end CNC bending machine.

Electro hydraulic servo CNC bending machine has become the most advanced product among many types of bending machines. Many high-demand products have strict requirements for multi-processing accuracy, and the electro hydraulic servo CNC bending machine came into being. Only the real electro hydraulic servo CNC bending machine can withstand the test of the high-standard market.

Related configuration

1. The hydraulic system can realize the rapid descending of the sliding block, the slow descending, the bending at the working speed, the rapid return and the emergency stop of the sliding block during the upward and downward process.

2. The oil pump adopts axial piston pump, which can withstand high pressure and low noise.

3. The sealing ring adopts international famous brand, which has good sealing performance, reliable operation and long service life.

4. The adjustment of the back gauge is driven by a servo motor, and driven by a ball screw after being decelerated by a gear, using a linear guide.

Related Products

Are there any products you like?

24 hours a day online service, let you satisfaction is our pursuit.