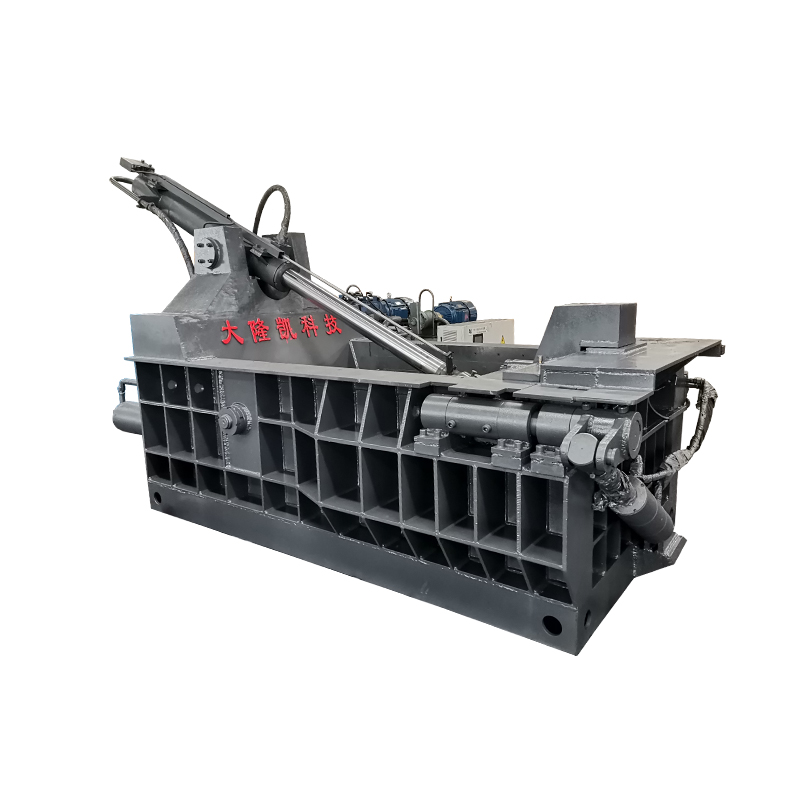

Product Description

This is a hydraulic metal baler with a forward turning device, and its master cylinder pressure is 250 tons. Y81 series hydraulic scrap metal balers are mainly used in scrap metal recycling yards, steel mills, scrap metal recycling and processing industries, etc. This metal baler can squeeze all kinds of scrap metal (scrap copper, scrap iron, scrap aluminum, etc., ranging from car shells to small metal scraps, etc.) into bales of uniform specifications.

Technical Parameters

|

NO. |

Parameter name and content |

||||

|

1 |

Main oil cylinder |

Model |

YG340/220 |

Qty. |

2pc |

|

Normal force |

2500KN |

Stroke |

730mm |

||

|

2 |

Side pressure cylinder |

Model |

YG240/160 |

Qty. |

2pc |

|

Normal force |

1100kN*2 |

Stroke |

2070mm |

||

|

3 |

Turning bag cylinder |

Model |

YG140/75 |

Qty. |

1pc |

|

Normal force |

120kN |

Stroke |

1900mm |

||

|

4 |

Door cover cylinder |

Model |

YG240/160 |

Qty. |

1pc |

|

Normal force |

1100kN |

Stroke |

320mm |

||

|

Flow |

16.3m³/h |

Qty. |

2900r/min |

||

|

5 |

Bale section size*minimum length |

(500×500)x600mm |

|||

|

6 |

Specification of material box (compression chamber) |

2500x2000x1000mm |

|||

|

7 |

Power Specifications |

380V/3P 50Hz |

|||

|

8 |

Total equipment power |

42.95kW |

|||

|

Frequency conversion motor, adjustable speed, automatic start and stop, feeding stop, power saving and energy saving. |

|||||

The parameters in the above table are for reference only.

Features of the scrap metal baler

1.Hydraulic drive, manual or PLC automatic control.

2.Bale-discharging:”turn-out” , “push-out” , “foward-out” & manual discharging.

3. No anchor bolts are required for equipment installation, which is convenient for production or equipment layout adjustment.

4. Can be equipped with diesel engine as backup power supply.

5.Pressing from three side,pressed bales will have a higher density.

6.Simple operation, efficient and safe.

Related Products

Are there any products you like?

24 hours a day online service, let you satisfaction is our pursuit.