-

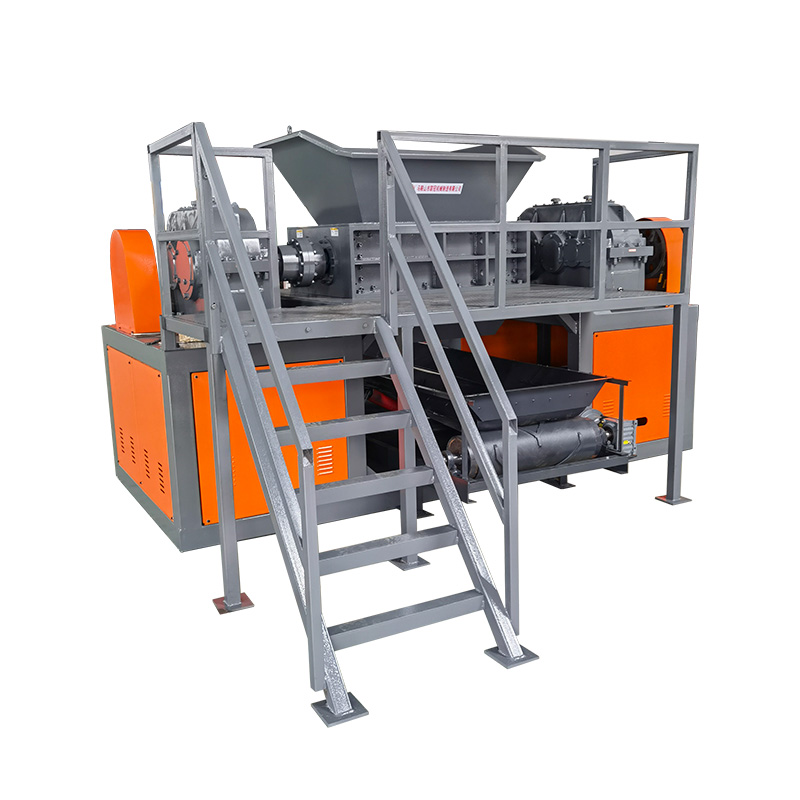

Y1035-30 Double Shaft Solid Waste Metal Shredder Industrial Scrap Shredder

Double shaft solid metal scrap shredder industrial waste shredder absorbs advanced technology and manual technology at home and abroad. To meet the requirements of different customers through biaxial shredding of materials. It can be used for all kinds of waste paper, waste wood, garden waste, kitchen waste, medical waste, waste tires, waste plastics, waste home appliances, waste oil drums, iron sheets, etc. The shredder can reduce the size of waste, saving transportation costs and space.

-

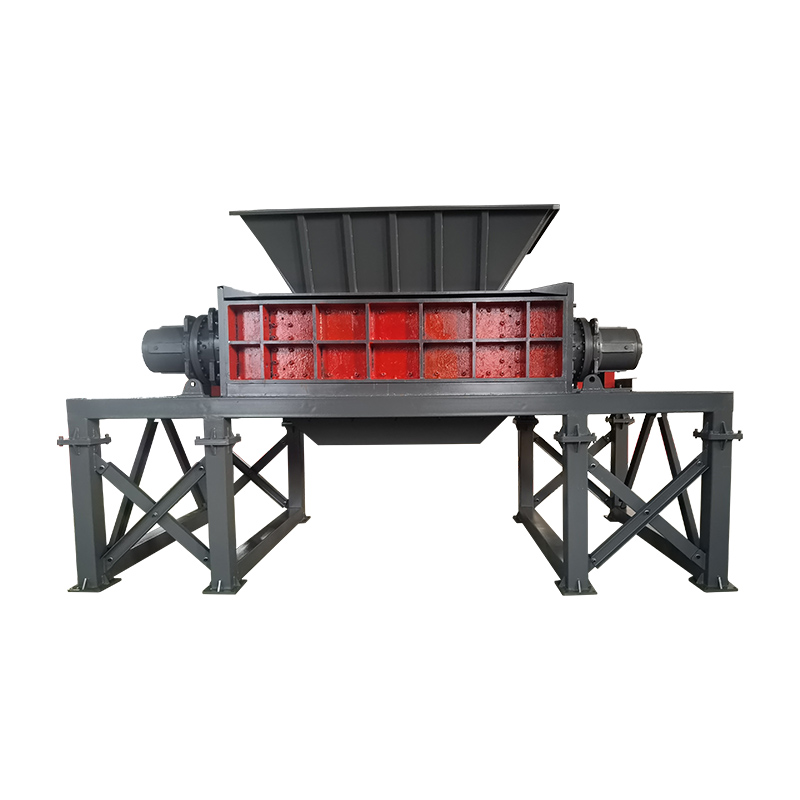

X1660-30 Scrap Metal Double Shaft Cardboard Shredder Wood Crusher Machine

Double-shaft shredder/metal shredder/metal can shredder, also known as shear type shredder, reduces the size of raw materials by cutting, tearing and squeezing.

-

GHY1265-80 Iron Scrap Plastic And Wood Metal Double Shaft Shredder Machine

The twin-shaft shredder achieves the purpose of reducing the size by cutting, tearing and squeezing the material. This shredder is widely used for large garbage such as waste plastics, rubber, and wood. Introduce the 30 years of experience in manufacturing such equipment in Europe and the United States into China, and carry out improvements and research and development based on actual conditions. The introduction of mature technology and advanced design of the double-shaft shredder series, waste recycling provides high quality for our pre-crushing and volume reduction treatment Reliable equipment.

-

GHY1260-80 Multifunctional Double Shaft Scrap Metal / Plastic / Car Shell Shredder

Double-shaft shredders are widely used to crush harder or larger materials. The double-shaft shredder adopts double-shaft independent drive, so that the material is compressed accordingly, and achieves the automatic feeding function. The unique cutter shaft structure and four-corner rotary cutter will prevent entanglement in the process of low speed and high torque. The phenomenon of shaft or stuck equipment, thereby improving efficiency. There are many advantages in environmental protection, recycling and other aspects.

-

F1240-50 Scrap Steel Paint Bucket Crusher Composite Plastic Bottle Metal Shredder

The double-shaft shredder can generally be used to shred solid materials such as plastic, rubber, fiber, paper, wood, electrical devices, cables, etc. that are difficult to break, such as nozzle materials, plastic heads, PET bottles, cardboard, circuit boards, wood , Plastic buckets, etc.

-

GHY1245-50 Twin Shaft Waste Scrap Metal Shredder Recycling Machine

The double-shaft shredder, also known as the shearing shredder, reduces the size of the material through cutting, tearing and squeezing. This shredder is widely used in waste plastics, waste rubber, wood and other large-volume wastes.

-

F1240-50 High Quality Plastic Recycling Shredder Machine

The double-shaft shredder can generally be used to shred solid materials such as plastic, rubber, fiber, paper, wood, electrical devices, cables, etc. that are difficult to break, such as nozzle materials, plastic heads, PET bottles, cardboard, circuit boards, wood , Plastic buckets, etc.

-

Waste Household Metal Recycling Crusher Car Lithium Battery Shredder

Double-shaft shredder is mainly composed of a movable knife roller (spindle + blade), a fixed knife, a crushing box, a box support, a feeding system, a power system, and an electrical control system. The dual-shaft shredder has a wide range of uses. Due to its low speed and large torque, it is suitable for crushing hard or large materials. Such as waste paper, waste wood, garden waste, kitchen waste, medical waste, waste tires, waste plastics, waste home appliances, waste oil drums, iron sheets, etc.

-

Scrap Baled Aluminum Hydraulic Double-shaft Shredder

双轴撕碎机的应用范围很广。可用于粉碎金属桶、塑料桶、木材、轮胎、汽车外壳、金属包装、硬盘、钢管、发动机外壳、废金属等。

-

DS Double-shaft Shredder For Metal Oil Drum

The double-shaft shredder can meet the waste recycling requirements of various industries and is suitable for shredding thick and difficult to shred materials. Such as waste paper, waste wood, garden waste, kitchen waste, medical waste, waste tires, waste plastics, waste home appliances, waste oil drums, iron sheets, etc.

-

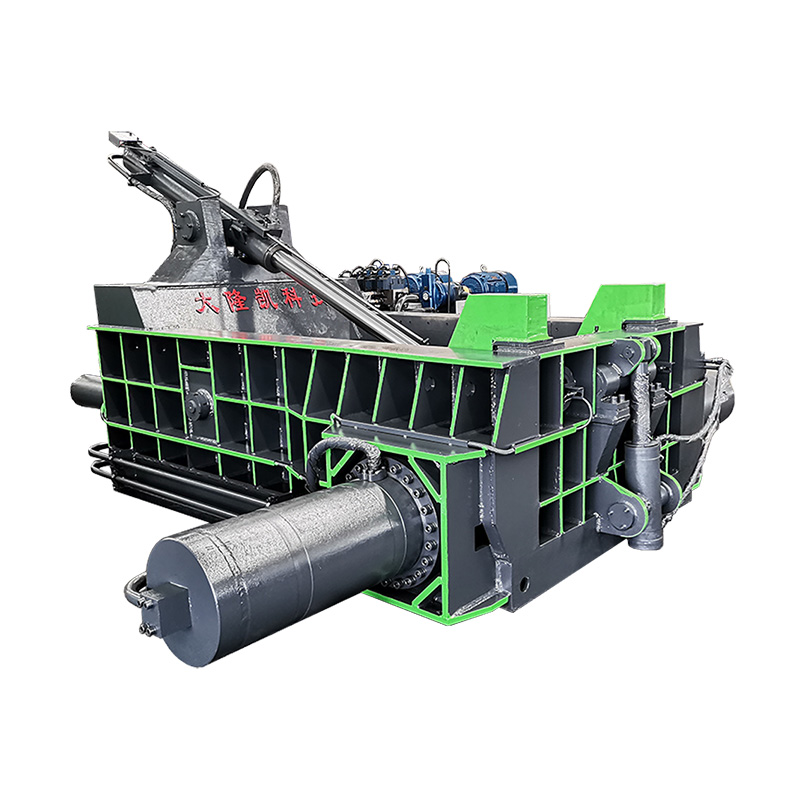

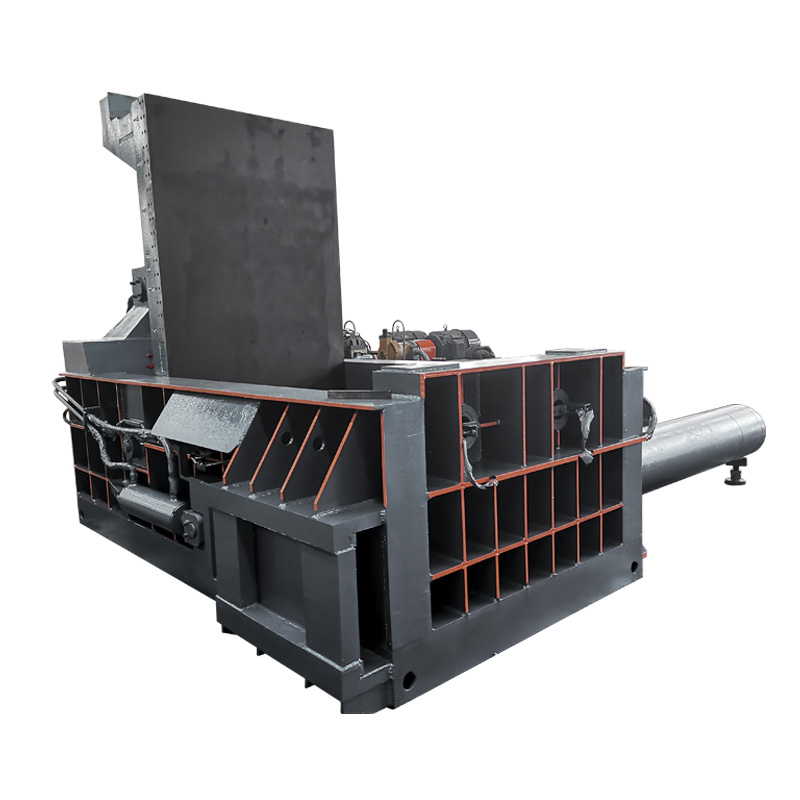

PLC Control Waste Metal Baling Press Machine For Recycling Plant

The metal hydraulic scrap baler can compress various scrap metal scraps and is an indispensable processing equipment in the scrap metal recycling industry. This 200-ton automatic forward-turning baler adopts a PLC control system and is easy to operate. After the machine completes a job, the bales can be automatically turned out of the bin, which greatly reduces the cost of manpower and material resources, and also reduces the cost of transportation and storage.

-

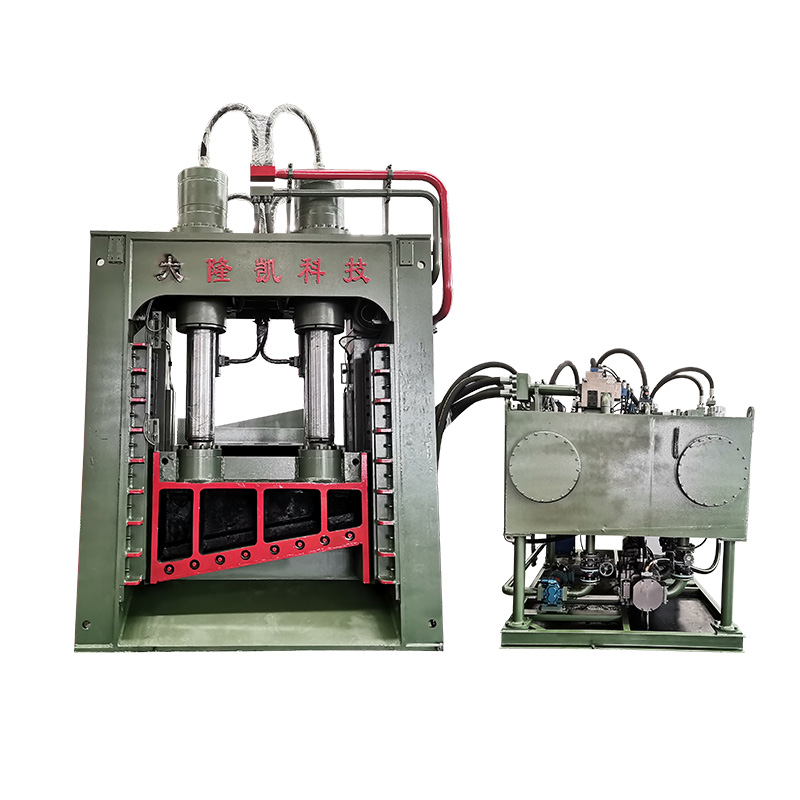

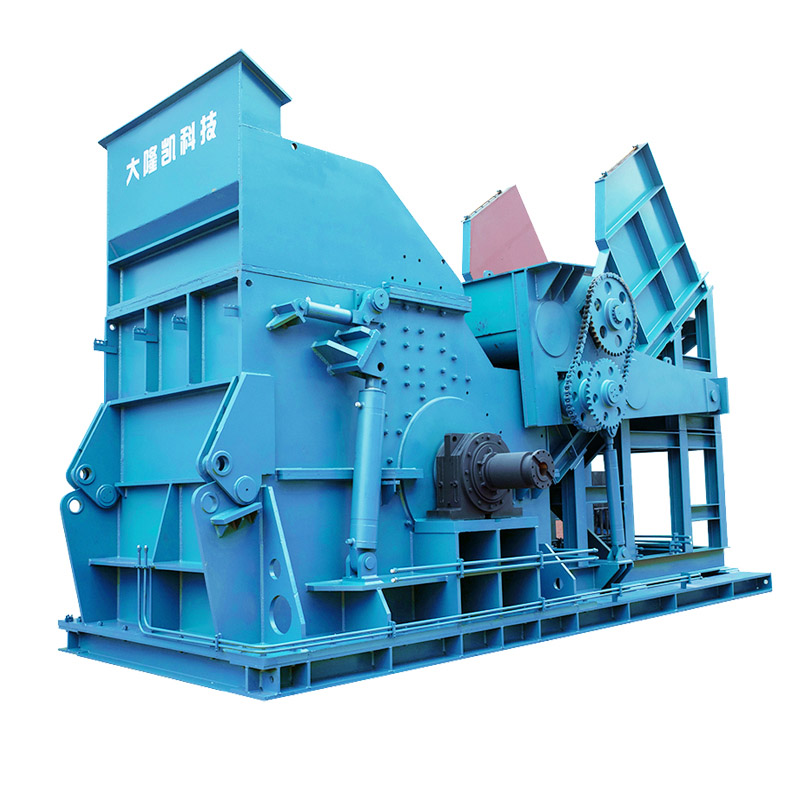

500 Tons Hydraulic Scrap Metal Cutter Machine OEM

Gantry hydraulic shear machine is compact in structure, and its body is made of steel plate welded into a box structure, with stable mechanical properties. The shear cylinder is connected by ball joint, which improves the stability and service life of the cylinder, adding the front plate guide device, and improves the stress condition of the whole machine. It is one of the ideal equipments in metal recovery industry and casting workshop for charge processing.

Recommended Products

Our machines are mainly suitable for scrapyards, steel mills, scrap recycling processing industry, and nonferrous & ferrous smelting industry.Are there any products you like?

24 hours a day online service, let you satisfaction is our pursuit.