-

Q91Y-500 Waste Steel Shear Cutting Machine

Gantry shears are hydraulically driven. Compared with mechanical transmission shears, they have the advantages of small size, light weight, low movement inertia, low noise, smooth movement, flexible operation, and large cutting section. Hydraulic and electric integrated control, can implement single, continuous action conversion, simple and convenient to use, can stop and run at any working position, easy to achieve overload protection.

-

Q91Y-1600 Heavy Scrap Metal Gantry Shear

Gantry hydraulic shear machine is compact in structure, and its body is made of steel plate welded into a box structure, with stable mechanical properties. The shear cylinder is connected by ball joint, which improves the stability and service life of the cylinder, adding the front plate guide device, and improves the stress condition of the whole machine. It is one of the ideal equipments in metal recovery industry and casting workshop for charge processing.

-

WS Mobile Integrated Box Type Scrap Metal Shearing Machine

WS series horizontal automatic shearing machine is suitable for metallurgy, steel mills, scrap metal recycling, renewable resources and other industries. WS metal shears can cut all kinds of light and thin materials, metal structural parts and domestic scrap steel. The integrated horizontal shears can be moved and can be equipped with diesel generators for normal use in places where there is no power supply.

-

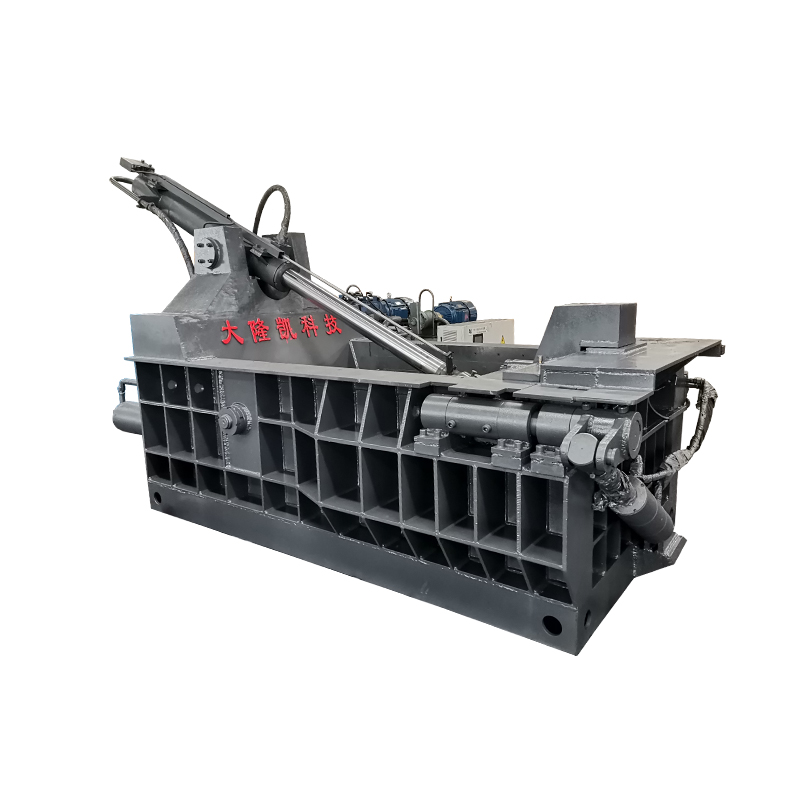

250 tons Hydraulic Waste Metal Baler Compactor Machine

The metal scrap baler machine adopts advanced hydraulic transmission technology, uses high-quality wear-resistant oil seals, and the oil cylinder is processed and assembled by the latest domestic high-tech technology to ensure continuous operation without reducing the pressure of the oil cylinder, durable and stable; it adopts PLC control and automation High degree, low failure rate, easy maintenance, etc. Various scrap metal scraps are directly cold-pressed and formed by high pressure, which is convenient for storage, transportation and recycling.

-

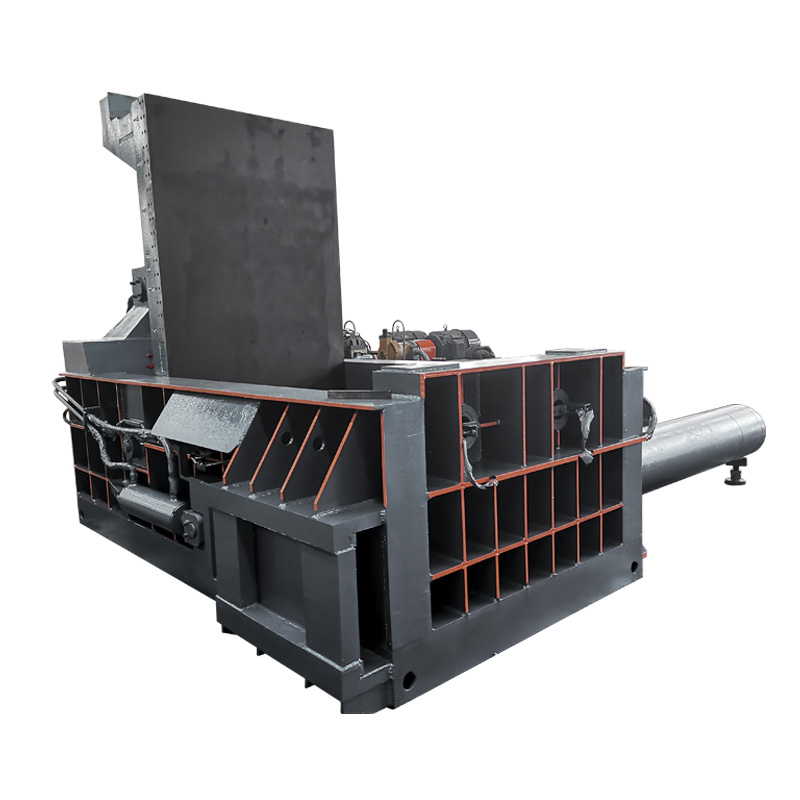

Small Waste Metal Pressing Machine For Recycling Plant

Y81 series metal hydraulic baler is capable of extruding various metal leftover materials, steel parting, waste copper, aluminum, copper, stainless steel and scraped car material into qualified charging such as square column, cylinder, octagon body and other sharps, in a bid to reduce transportation,refine costs and increase transportation speed.

-

Automatic Pushing-out Bale Metal Baler Pressing Machine

The metal baler can squeeze a variety of metal shavings, steel shavings, aluminum shavings, copper shavings, etc. into rectangular, cylindrical, octagonal and other shapes of qualified charging to reduce transportation and torch costs.

-

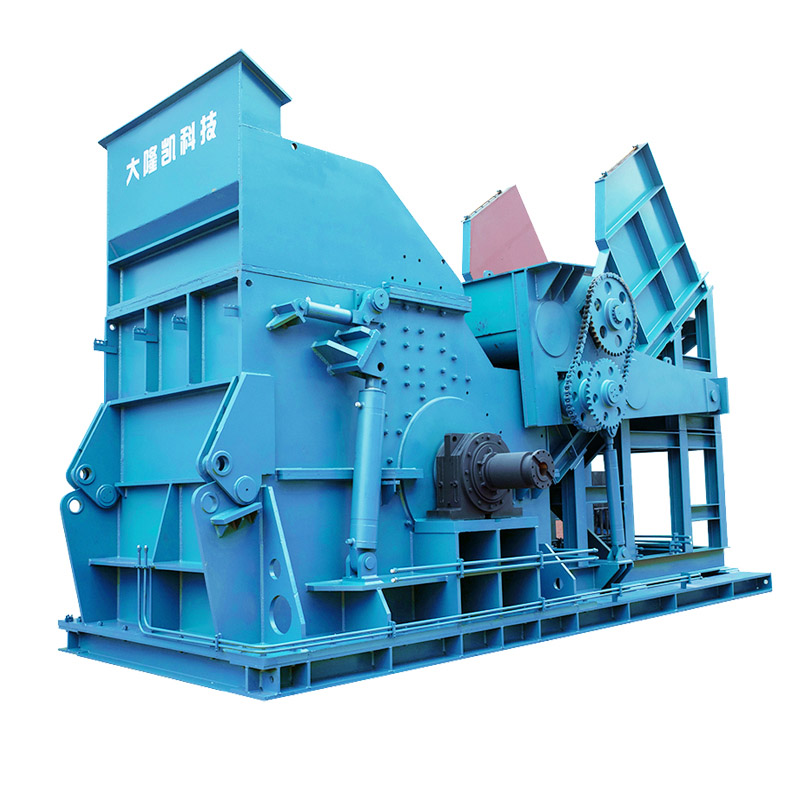

Hydraulic Waste Scrap Metal Shredding Lines Recycling Shredder

PSX series scrap steel crushing line is used to process inferior scrap materials such as scrap car bodies, tinplates, old household appliances, bicycles, and empty cans to make them into first-class steel-making raw materials. Through continuous crushing, removing the coating film, increasing the specific gravity, preventing explosion when putting into the electric furnace, increasing the probability of dissolution under certain conditions, etc., it can meet the requirements of steel mills for “fine material putting into the furnace”.

-

HPM Waste paper baler machine

Waste paper baler machine is mainly used for the recovery of compressed cardboard, waste film, waste paper, foam plastics, beverage cans and industrial waste and other packaging materials and waste products. The baler reduces waste storage space, saves up to 80% of the storage space, reduces transportation costs, and is favorable for environmental protection and waste recycling.

-

Hydraulic Vertical Waste Cardboard Baler Press Machine

Vertical hydraulic baler is mainly used to recycle packaging materials and waste products such as compressed cardboard, waste film, waste paper, foam plastic, beverage cans and industrial scraps. This vertical baler reduces waste storage space, saves up to 80% of stacking space, reduces transportation costs, and is conducive to environmental protection and waste recycling.

-

Crushing Metal Shredder Machine / Hydraulic Scrap Metal Grinder

The shredder is designed to shred a wide variety of light and thin materials as discarded automobiles, tin plate, household appliances, bicycles, empty cans, etc, making the materials into pure charge for steelmaking. By smashing and compressing, the shredder will remove the impurities, raise density, lower transporting and smelting cost to offer good furnace charge for steel plant.

-

Double Cylinder Metal Briquetting Press Machine

Y83 series horizontal double main cylinder cake press can process scraps, including copper, steel, aluminum, purple and brass. In addition, it can also process the mixture of grinding slurry and metal scraps.

-

Manual Pick Up 2500kg Scrap Matal Steel Press Machine

We specialize in the production of large-scale hydraulic machinery and equipment. The balers include scrap steel balers, scrap car briquetting machines, scrap iron briquetting machines, metal shavings balers, scrap metal briquetting machines, scrap steel compression balers, etc., suitable for steel mills , Recycling and processing industries and non-ferrous and ferrous metal smelting industries. Various metal scraps, steel shavings, scrap steel, scrap aluminum, scrap copper, etc. can be extruded into rectangular, cylindrical, octagonal, and other shapes of qualified charge to reduce transportation and torch costs.

Recommended Products

Our machines are mainly suitable for scrapyards, steel mills, scrap recycling processing industry, and nonferrous & ferrous smelting industry.Are there any products you like?

24 hours a day online service, let you satisfaction is our pursuit.