-

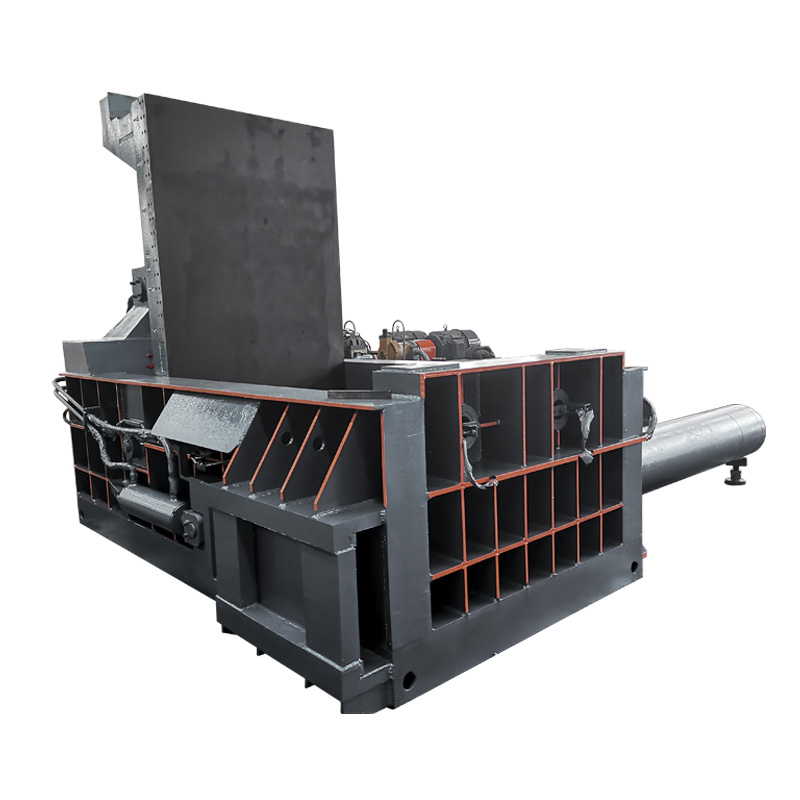

Semi-automatic Scrap Metal Baler Recycling Machine

Y81K-630 hydraulic metal baler is mainly suitable for scrap metal recycling plants. This machine adopts PLC control system with high efficiency and easy operation, which can be operated by one person. The double main cylinder presses the material, and the pressed block has a compact structure and high density. After the packing is completed, the bales are discharged by manual taking out. Most customers will also be equipped with claw machines or suction cups to take out the bales.

-

WS Series Horizontal Automatic Shearing Machine

This horizontal container shearing machine is suitable for cutting metals with different cross-sectional shapes, such as round, square, trough, angle, I-shaped, plate and various cold-state waste and old structural metals. It brings convenience to the packaging, storage and transportation of scrap metal materials, and also provides qualified charge for smelters. This machine has a wide range of applications, and is often used in metal recovery devices, factory foundries and processing equipment in the machinery manufacturing industry.

-

Q43 Series Crocodile Alligator Shearing Machine

Q43 series of hydraulic alligator shears are applied in recycling companies, automobile dismantling plants, smelting & casting industry to cold-shear section steel and metallic structural parts, to produce acceptable furnace charges.

-

WS-630 Hydraulic Container Shear For Heavy Scrap

The box shear is an efficient scrap processing equipment. The box-type shearing machine has a compact structure and an integrated design that is easy to move. It can be controlled by a hybrid engine and a motor, or can be controlled separately by an engine or a motor. The biggest advantage of box shear is its high overall utilization rate.

-

HPM Waste paper baler machine

Waste paper baler machine is mainly used for the recovery of compressed cardboard, waste film, waste paper, foam plastics, beverage cans and industrial waste and other packaging materials and waste products. The baler reduces waste storage space, saves up to 80% of the storage space, reduces transportation costs, and is favorable for environmental protection and waste recycling.

-

Hydraulic Vertical Waste Cardboard Baler Press Machine

Vertical hydraulic baler is mainly used to recycle packaging materials and waste products such as compressed cardboard, waste film, waste paper, foam plastic, beverage cans and industrial scraps. This vertical baler reduces waste storage space, saves up to 80% of stacking space, reduces transportation costs, and is conducive to environmental protection and waste recycling.

-

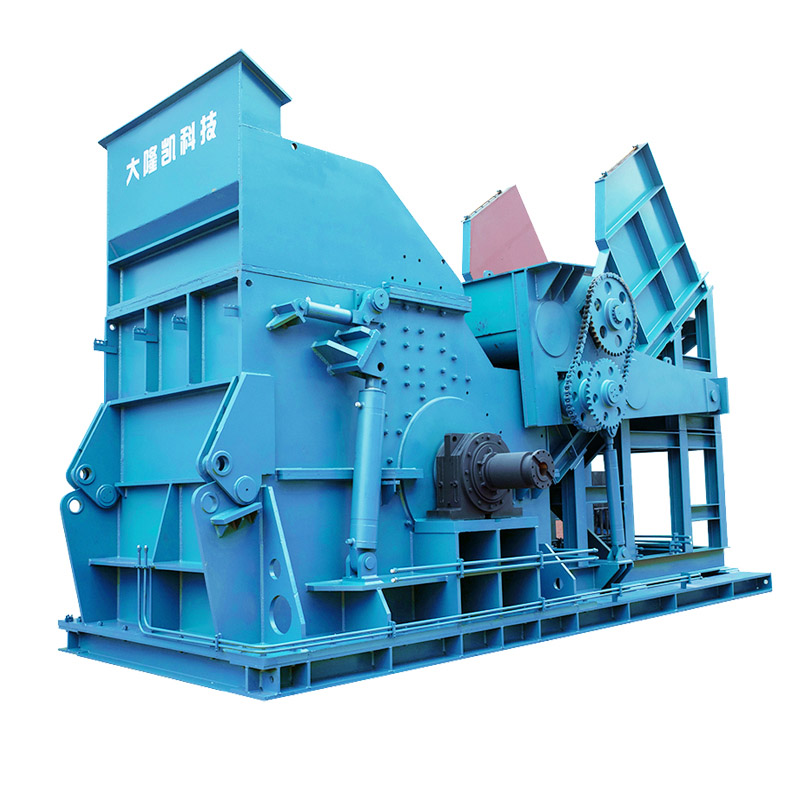

Crushing Metal Shredder Machine / Hydraulic Scrap Metal Grinder

The shredder is designed to shred a wide variety of light and thin materials as discarded automobiles, tin plate, household appliances, bicycles, empty cans, etc, making the materials into pure charge for steelmaking. By smashing and compressing, the shredder will remove the impurities, raise density, lower transporting and smelting cost to offer good furnace charge for steel plant.

-

Double Cylinder Metal Briquetting Press Machine

Y83 series horizontal double main cylinder cake press can process scraps, including copper, steel, aluminum, purple and brass. In addition, it can also process the mixture of grinding slurry and metal scraps.

Recommended Products

Our machines are mainly suitable for scrapyards, steel mills, scrap recycling processing industry, and nonferrous & ferrous smelting industry.Are there any products you like?

24 hours a day online service, let you satisfaction is our pursuit.