Scrap Metal Baler

-

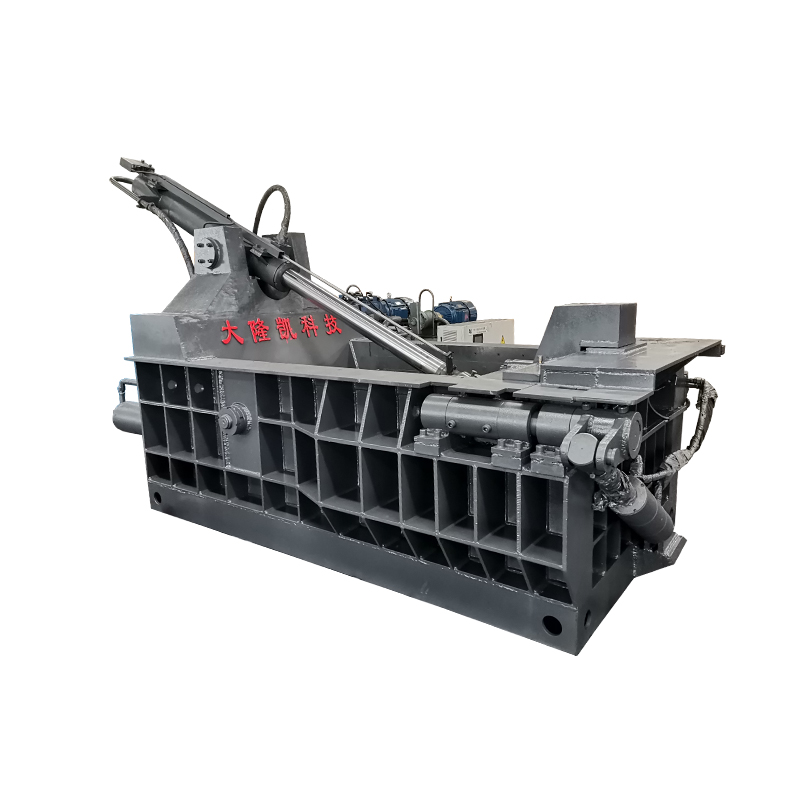

250 tons Hydraulic Waste Metal Baler Compactor Machine

The metal scrap baler machine adopts advanced hydraulic transmission technology, uses high-quality wear-resistant oil seals, and the oil cylinder is processed and assembled by the latest domestic high-tech technology to ensure continuous operation without reducing the pressure of the oil cylinder, durable and stable; it adopts PLC control and automation High degree, low failure rate, easy maintenance, etc. Various scrap metal scraps are directly cold-pressed and formed by high pressure, which is convenient for storage, transportation and recycling.

-

Small Waste Metal Pressing Machine For Recycling Plant

Y81 series metal hydraulic baler is capable of extruding various metal leftover materials, steel parting, waste copper, aluminum, copper, stainless steel and scraped car material into qualified charging such as square column, cylinder, octagon body and other sharps, in a bid to reduce transportation,refine costs and increase transportation speed.

-

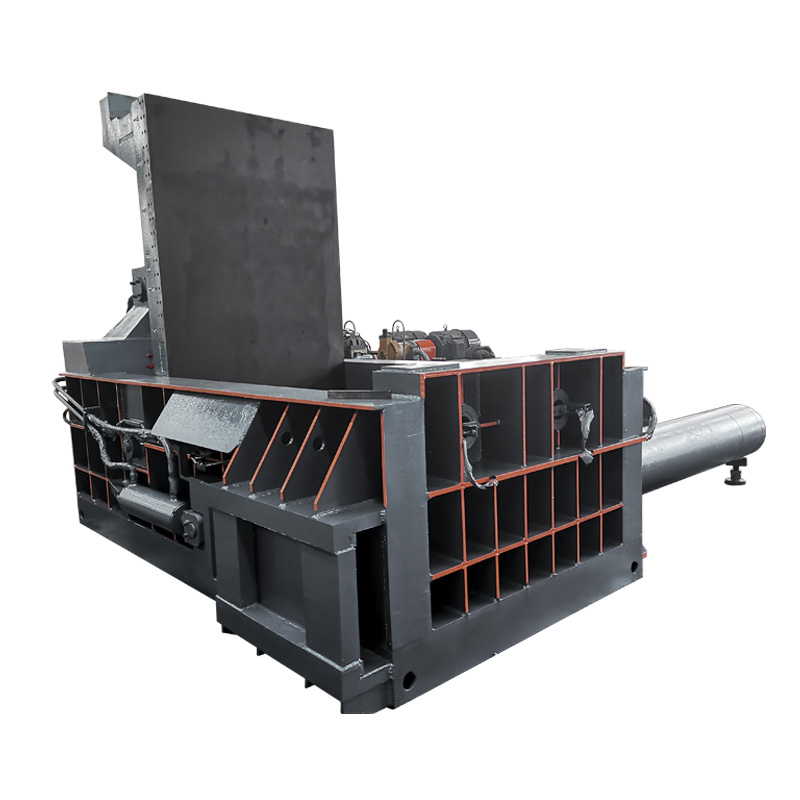

Automatic Pushing-out Bale Metal Baler Pressing Machine

The metal baler can squeeze a variety of metal shavings, steel shavings, aluminum shavings, copper shavings, etc. into rectangular, cylindrical, octagonal and other shapes of qualified charging to reduce transportation and torch costs.

-

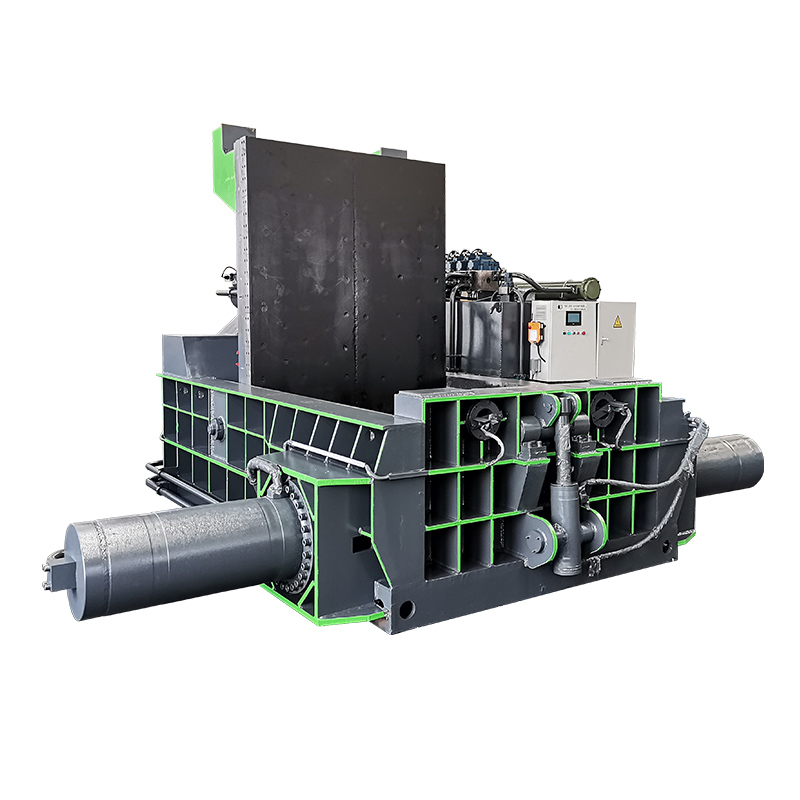

Y81 Series Hydraulic Scrap Metal Baler For Recycling Industry

Y81 series metal hydraulic baler is capable of extruding various metal leftover materials, steel parting, waste copper, aluminum, copper, stainless steel and scraped car material into qualified charging such as square column, cylinder, octagon body and other sharps, in a bid to reduce transportation,refine costs and increase transportation speed.

-

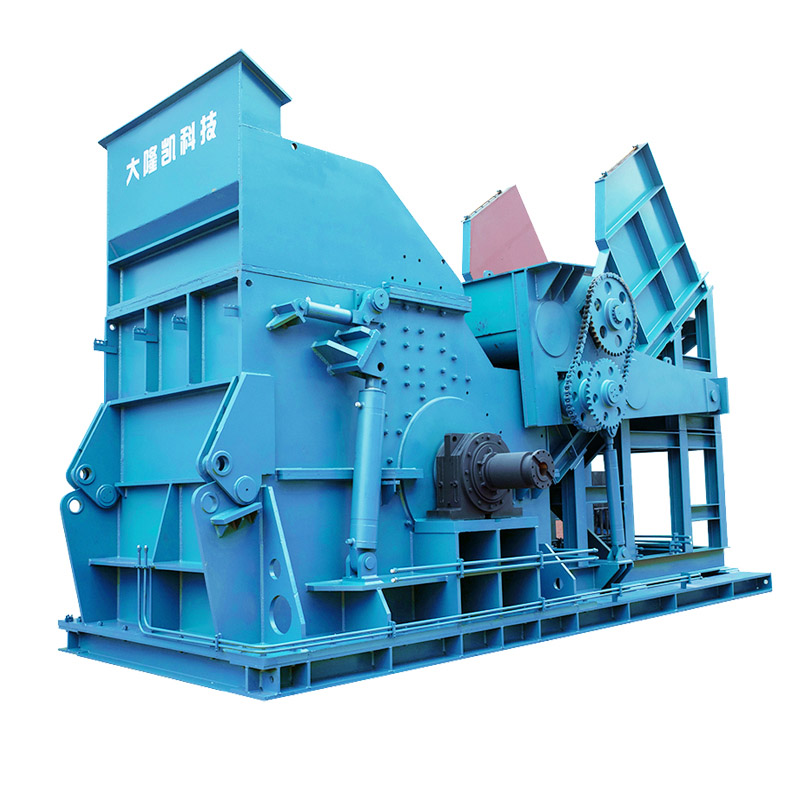

Manual Pick Up 2500kg Scrap Matal Steel Press Machine

We specialize in the production of large-scale hydraulic machinery and equipment. The balers include scrap steel balers, scrap car briquetting machines, scrap iron briquetting machines, metal shavings balers, scrap metal briquetting machines, scrap steel compression balers, etc., suitable for steel mills , Recycling and processing industries and non-ferrous and ferrous metal smelting industries. Various metal scraps, steel shavings, scrap steel, scrap aluminum, scrap copper, etc. can be extruded into rectangular, cylindrical, octagonal, and other shapes of qualified charge to reduce transportation and torch costs.

-

Semi-automatic Scrap Metal Baler Recycling Machine

Y81K-630 hydraulic metal baler is mainly suitable for scrap metal recycling plants. This machine adopts PLC control system with high efficiency and easy operation, which can be operated by one person. The double main cylinder presses the material, and the pressed block has a compact structure and high density. After the packing is completed, the bales are discharged by manual taking out. Most customers will also be equipped with claw machines or suction cups to take out the bales.

-

Semi-automatic Scrap Metal Baler Recycling Machine

Y81K-315 hydraulic metal baler is mainly suitable for small scrap metal recycling plants. This machine adopts PLC control system with high efficiency and easy operation, which can be operated by one person. The double main cylinder presses the material, and the pressed block has a compact structure and high density. After the packing is completed, the bales are discharged by manual taking out. Most customers will also be equipped with claw machines or suction cups to take out the bales.

-

Automatic Metal Baler Pressing Machine

Y81QF-250 hydraulic metal baler is one of our more popular small balers. This machine adopts PLC control system, high efficiency, convenient operation, and can be operated by one person. Double main oil cylinders press material, compact structure and high density. The front of the material box is equipped with a material turning oil cylinder, which automatically turns out the material box after the material box is formed.

Recommended Products

Our machines are mainly suitable for scrapyards, steel mills, scrap recycling processing industry, and nonferrous & ferrous smelting industry.Are there any products you like?

24 hours a day online service, let you satisfaction is our pursuit.