Shear Machine

-

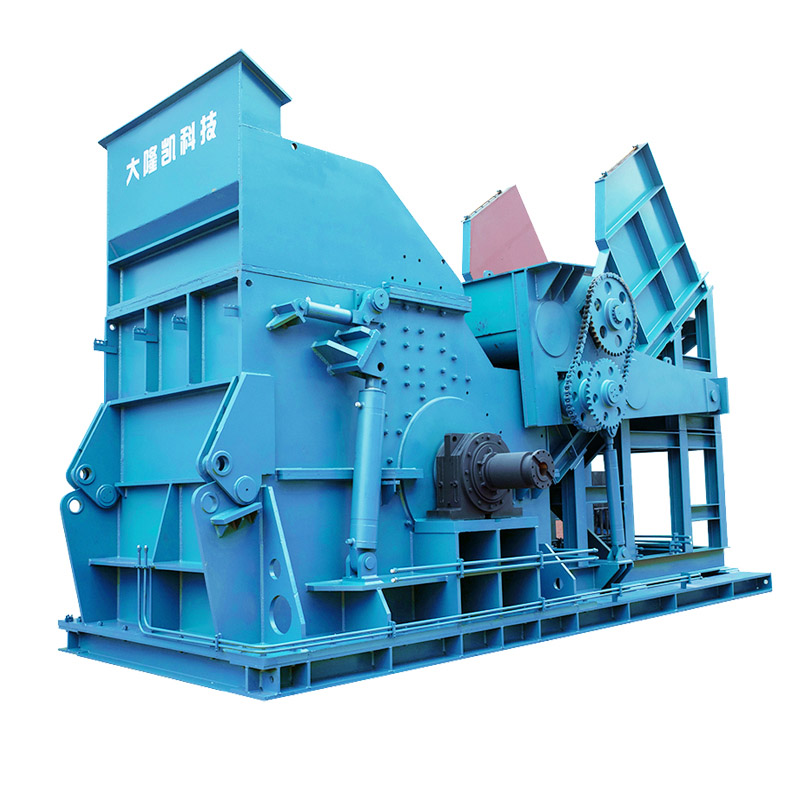

Heavy Duty Guillotine Scrap Steel Copper Aluminum Metal Shear Machine

Q91Y series heavy hydraulic shearing machine is a medium-sized scrap steel shearing machine with a wide range of cutting materials and high processing capacity. Its powerful processing capacity is favored by scrap steel processing enterprises. The gantry shears use sophisticated materials and complex manufacturing processes, which have strict requirements for the machining capabilities of the factory and the technical level of the workers.

-

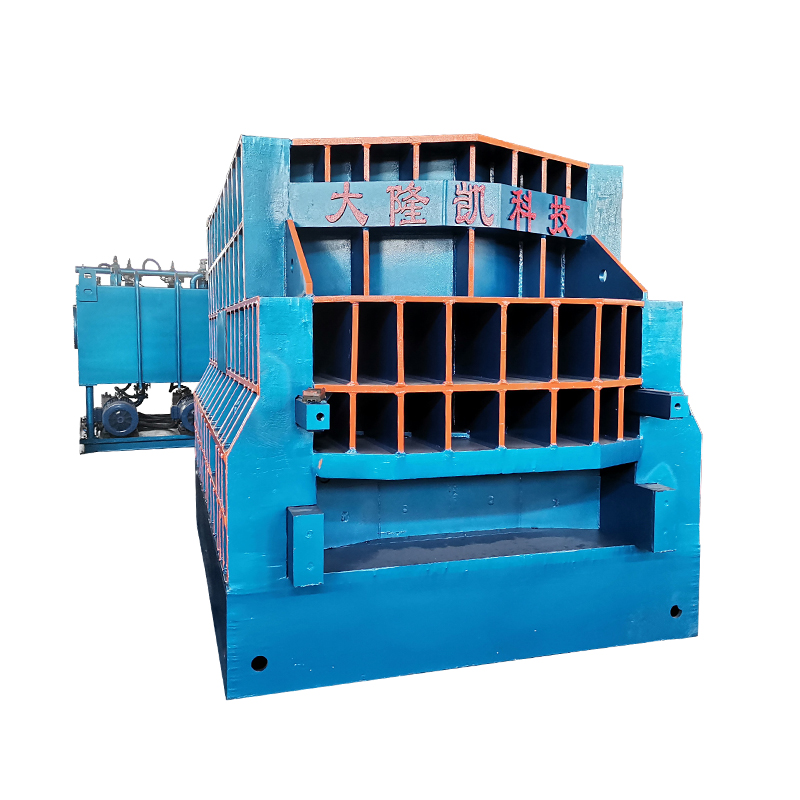

Hydraulic Gantry Metal Shear Guillotine Shear Iron Cutting Machine

The Q91Y-500 Gantry Shear is a kind of equipment suitable for the shearing and crushing of heavy steel scrap. The application of this machine solves the problem of crushing and recycling of large heavy waste furnace materials. It is widely used in rolling mills, metallurgical plants, and scrap steel processing and recycling units. It is an effective equipment for metallurgical charge processing and profile cutting.

-

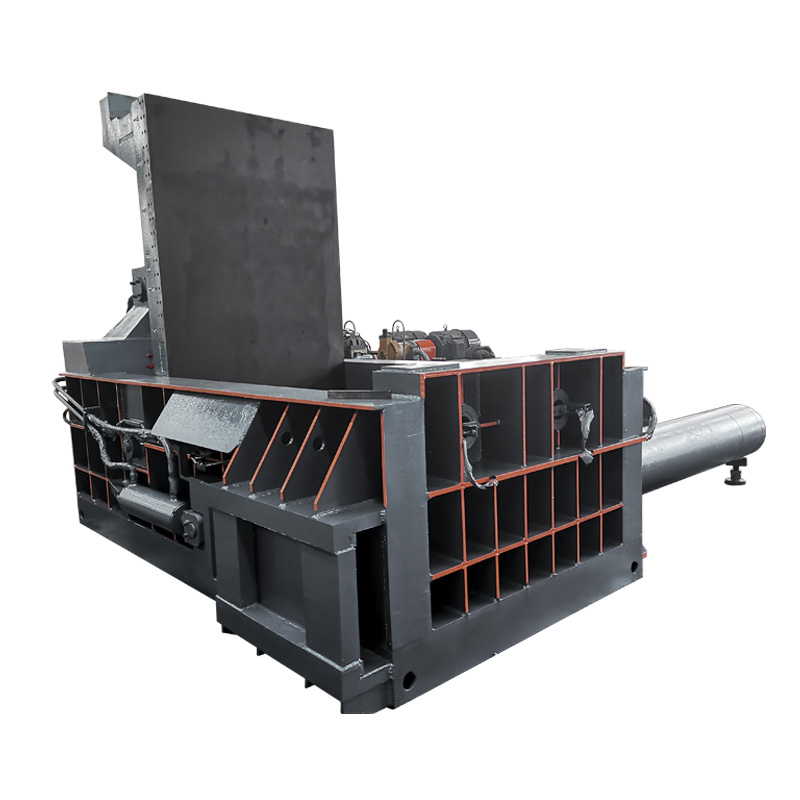

WS-800 Scrap Metal Container Shearing Machine

WS series container shearing machine is suitable for steel ingots, steel blanks and parts of heavy machinery for cutting heads and tails, various steels and their cutting heads, trimming ship plates, various machine scraps, rails, train wheels, and other agricultural machinery, steel furniture, etc. Small scrap steel such as utensils and tools.

-

Q91Y-500 Hydraulic Heavy Gantry Shear Machinery Shearing Metal Scrap Iron

The Q91Y-500 Gantry Shear is a kind of equipment suitable for the shearing and crushing of heavy steel scrap. The application of this machine solves the problem of crushing and recycling of large heavy waste furnace materials. It is widely used in rolling mills, metallurgical plants, and scrap steel processing and recycling units. It is an effective equipment for metallurgical charge processing and profile cutting.

-

Q91Y-630 Heavy Duty Shear Cutting Machine

Heavy-duty hydraulic shears are suitable for compressing and cutting thin & light materials, production and living scrap steel, light metal structural parts, scrap car body, wheel hub, old home alliances, plastic non-ferrous metals(stainless steel, aluminum alloy, copper, etc), or used to compress and bale the above mentioned materials.

-

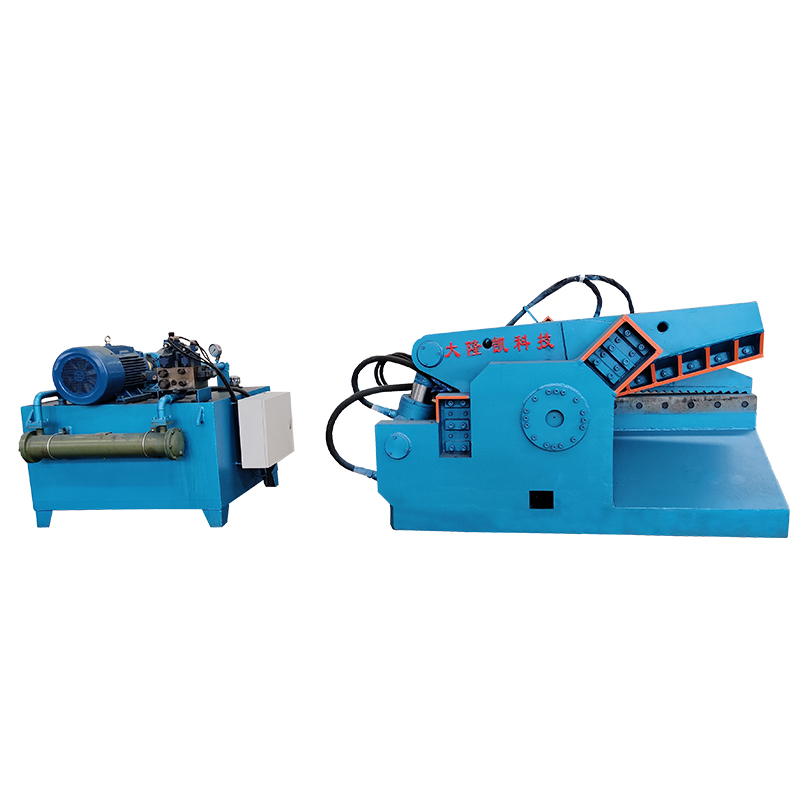

Q43 Crocodile Scissors Hydraulic Alligator Shearing Machine For Scrap Metal Cutting

The alligator shears can cut various shapes of steel and various metal structural parts in a cold state. The equipment adopts hydraulic transmission. Compared with the mechanical transmission shearing machine, it has the advantages of small size, light weight, low inertia, low noise, smooth movement, convenient operation, flexibility, large cutting section, and convenient adjustment of the scissors mouth. It is safe to operate and use , It is easy to realize overload protection. The alligator shears have manual and automatic functions, convenient and simple operation and control. The cutting mouth can start cutting and stopping at any position during the work process. According to the size of the material to be cut, the size of the cutting mouth can be arbitrarily controlled to achieve the highest Work efficiency.

-

Shear Cutter Machine Hydraulic Metal Shearing Machine

The alligator shear is a kind of mechanical equipment used to cut metal materials. In the rolling production process, after rolling large-section steel ingots and billets, the section becomes smaller and the length increases. In order to meet the requirements of subsequent processes and product size specifications, various steel production processes must have a shearing process.

-

Alligator Metal Sheet Shear Hydraulic Steel Shearing Machine

The alligator shearing machine is a kind of metal shearing machine, which adopts hydraulic drive, reliable safety performance and convenient operation. It is commonly used in waste recycling companies, scrap steel plants, smelting and foundry companies to perform cold shearing of various shapes of steel and various structural metals to add engineering qualified charge and materials.

-

500T Heavy Hydraulic Gantry Shear Scrap Metal Cutting Machine

Q91Y series hydraulic gantry shears can cut all kinds of scrap metal and steel.

-

Q91Y-500 Hydraulic Scrap I-beam Shear Cutting Machine

Gantry shears are used for cutting various metal plates. They are ideal equipment for charge processing in rolling mills, non-ferrous metal plants, and smelters. Our shearing machine models are complete and can also be customized according to customer needs. All models are hydraulically driven, PLC automatic control operation. The size of the material box is large, and the range of the material size that can be processed is large.

-

WS-630 Scrap Metal Hydraulic Box Shear For Recycling Industry

Box shearing machine is a new type of shearing equipment for efficiently processing bulk steel and metal scrap. The box-type shearing machine saves a lot of labor costs while closing the cutting and completely avoiding the danger of manual operation, increasing the production efficiency by 10 times, ensuring that the scrap can be quickly recycled and processed to meet the requirements of the refined material into the furnace, and with Comes with a series of benefits such as energy saving, environmental protection and economy.

-

Full Automatic PLC Control Heavy Scrap Metal Container shearing Machine

Container Box shears have a wide range of applications and are mostly used in the scrap metal recycling industry. Box shearing machine can cut all kinds of thin and light materials, metal structural parts and scrap steel of daily necessities. The hydraulic system is mainly composed of pump station, valve station, fuel tank, hydraulic pipeline, etc. The pipeline is welded with imported steel plate, so it is more convenient and quick to maintain and clean the fuel tank. The steel pipe adopts seamless high-pressure oil pipe, which can last longer.

Recommended Products

Our machines are mainly suitable for scrapyards, steel mills, scrap recycling processing industry, and nonferrous & ferrous smelting industry.Are there any products you like?

24 hours a day online service, let you satisfaction is our pursuit.