Shear Machine

-

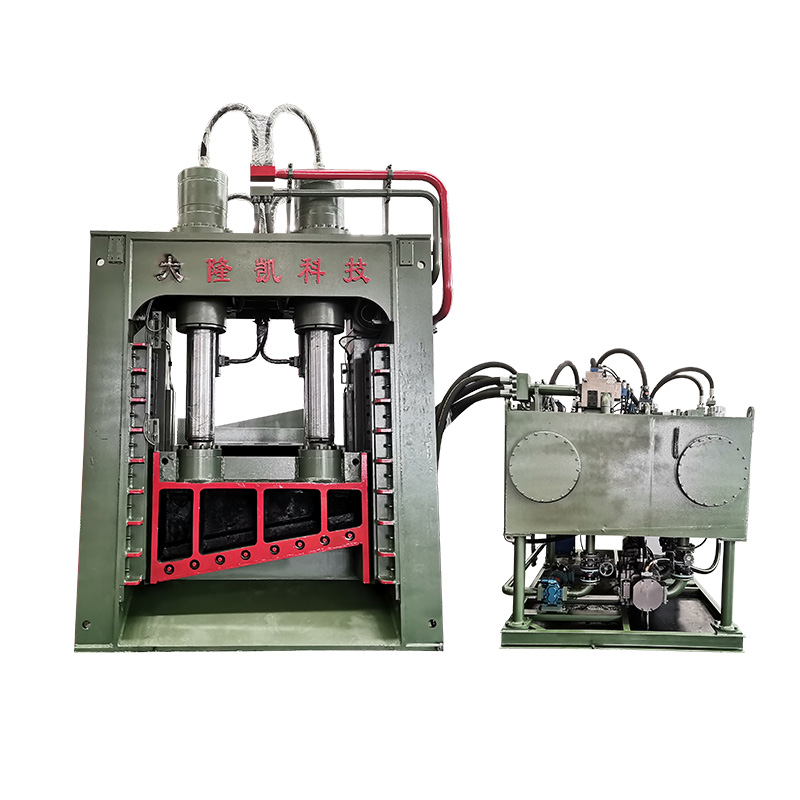

500 Tons Hydraulic Scrap Metal Cutter Machine OEM

Gantry hydraulic shear machine is compact in structure, and its body is made of steel plate welded into a box structure, with stable mechanical properties. The shear cylinder is connected by ball joint, which improves the stability and service life of the cylinder, adding the front plate guide device, and improves the stress condition of the whole machine. It is one of the ideal equipments in metal recovery industry and casting workshop for charge processing.

-

Q91Y-500 Waste Steel Shear Cutting Machine

Gantry shears are hydraulically driven. Compared with mechanical transmission shears, they have the advantages of small size, light weight, low movement inertia, low noise, smooth movement, flexible operation, and large cutting section. Hydraulic and electric integrated control, can implement single, continuous action conversion, simple and convenient to use, can stop and run at any working position, easy to achieve overload protection.

-

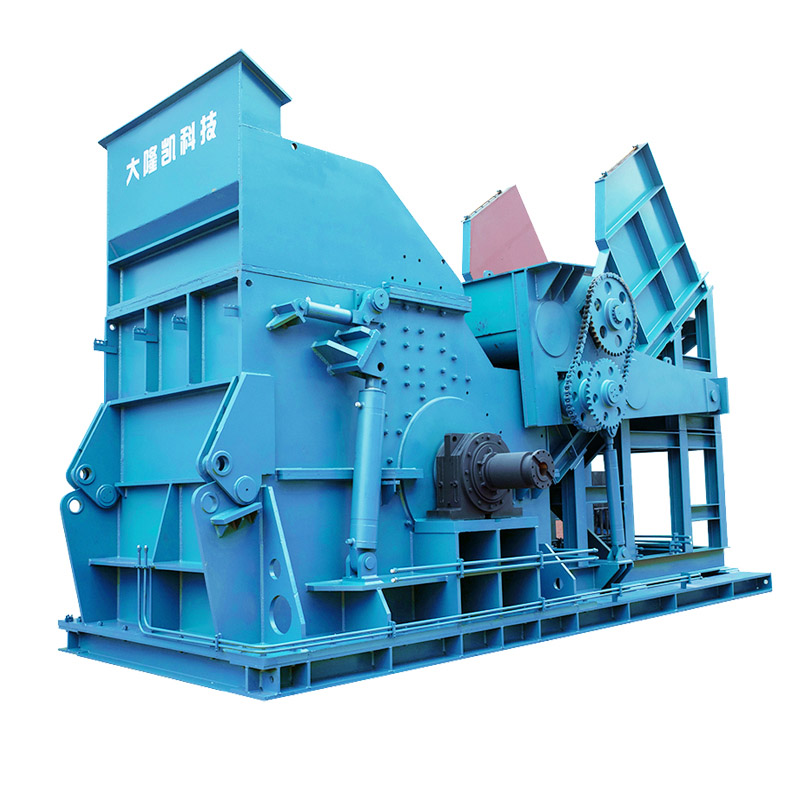

Q91Y-1600 Heavy Scrap Metal Gantry Shear

Gantry hydraulic shear machine is compact in structure, and its body is made of steel plate welded into a box structure, with stable mechanical properties. The shear cylinder is connected by ball joint, which improves the stability and service life of the cylinder, adding the front plate guide device, and improves the stress condition of the whole machine. It is one of the ideal equipments in metal recovery industry and casting workshop for charge processing.

-

WS Mobile Integrated Box Type Scrap Metal Shearing Machine

WS series horizontal automatic shearing machine is suitable for metallurgy, steel mills, scrap metal recycling, renewable resources and other industries. WS metal shears can cut all kinds of light and thin materials, metal structural parts and domestic scrap steel. The integrated horizontal shears can be moved and can be equipped with diesel generators for normal use in places where there is no power supply.

-

Heavy-duty Hydraulic Scrap Steel Gantry Shearing Machine

Heavy-duty hydraulic shears are suitable for light and thin materials, production and life scrap steel, light metal structural parts, scrap car bodies, wheels, old home alliances, plastic non-ferrous metals (stainless steel, aluminum alloy, copper, etc.), or used to compress and pack the above materials.

-

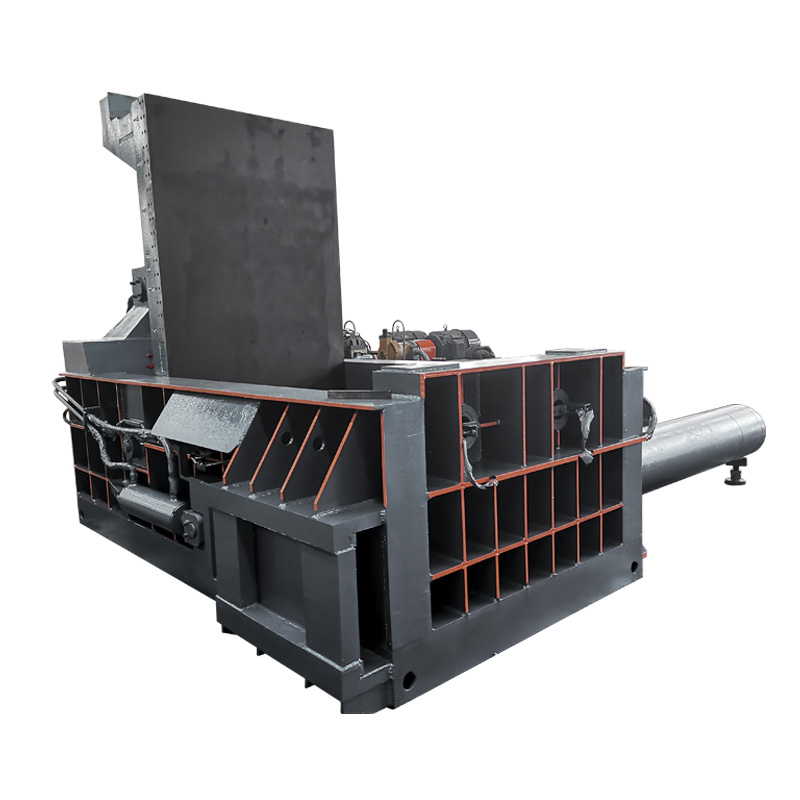

WS Series Horizontal Automatic Shearing Machine

This horizontal container shearing machine is suitable for cutting metals with different cross-sectional shapes, such as round, square, trough, angle, I-shaped, plate and various cold-state waste and old structural metals. It brings convenience to the packaging, storage and transportation of scrap metal materials, and also provides qualified charge for smelters. This machine has a wide range of applications, and is often used in metal recovery devices, factory foundries and processing equipment in the machinery manufacturing industry.

-

Q43 Series Crocodile Alligator Shearing Machine

Q43 series of hydraulic alligator shears are applied in recycling companies, automobile dismantling plants, smelting & casting industry to cold-shear section steel and metallic structural parts, to produce acceptable furnace charges.

-

WS-630 Hydraulic Container Shear For Heavy Scrap

The box shear is an efficient scrap processing equipment. The box-type shearing machine has a compact structure and an integrated design that is easy to move. It can be controlled by a hybrid engine and a motor, or can be controlled separately by an engine or a motor. The biggest advantage of box shear is its high overall utilization rate.

Recommended Products

Our machines are mainly suitable for scrapyards, steel mills, scrap recycling processing industry, and nonferrous & ferrous smelting industry.Are there any products you like?

24 hours a day online service, let you satisfaction is our pursuit.