Introduction

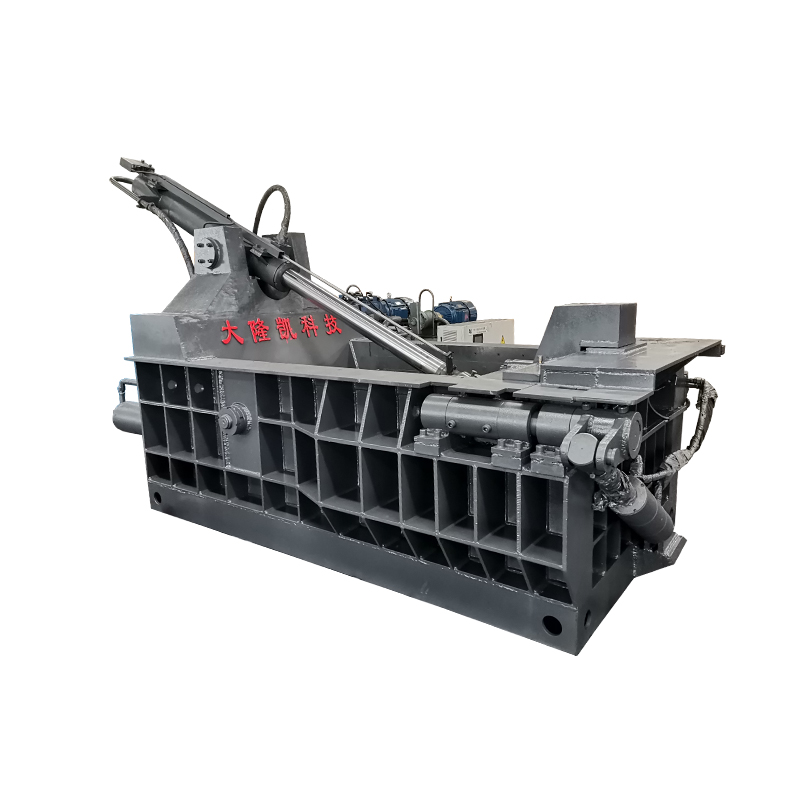

This Y81 scrap metal baler is a semi-automatic baler with single main cylinder side discharge. This baler adopts hydraulic drive and PLC automatic control system, which can be operated by one person, which saves labor costs. The hydraulic station of the machine is floor-standing. The cooling system uses a tube cooler. The feature of this tube cooler is that the water used for cooling flows through the inside of the tube, while the oil flows through the interval between the tubes, and the baffle plate set in the middle allows the oil to deflect. , the two-way or even four-way flow it uses makes its cooling effect more intense. The motor selected by the machine is a servo motor. The biggest advantage of this motor is energy saving and power saving, which can effectively save the production cost of customers. Our machine accessories are all well-known brands at home and abroad, with guaranteed quality, and can also be customized according to customer needs.

Technical Parameters

|

NO. |

Parameter name and content |

|

|

1 |

hydraulic system working pressure | ≤26MPa |

|

2 |

Press box size | 2500×2000×1000mm |

|

3 |

Block section size | (300x300)mm |

|

4 |

Bale density (steel) | ≤2000/m³ |

|

5 |

Single no-load cycle time | About 90 seconds |

|

6 |

Operation method | Hand-in-one, remote control operation |

The parameters in the above table are for reference only.

Application

The scrap metal baler can baling various scrap metal scraps, such as steel shavings, scrap steel, scrap aluminum, scrap copper, scrap stainless steel and scrap car shells.

Related Products

Are there any products you like?

24 hours a day online service, let you satisfaction is our pursuit.