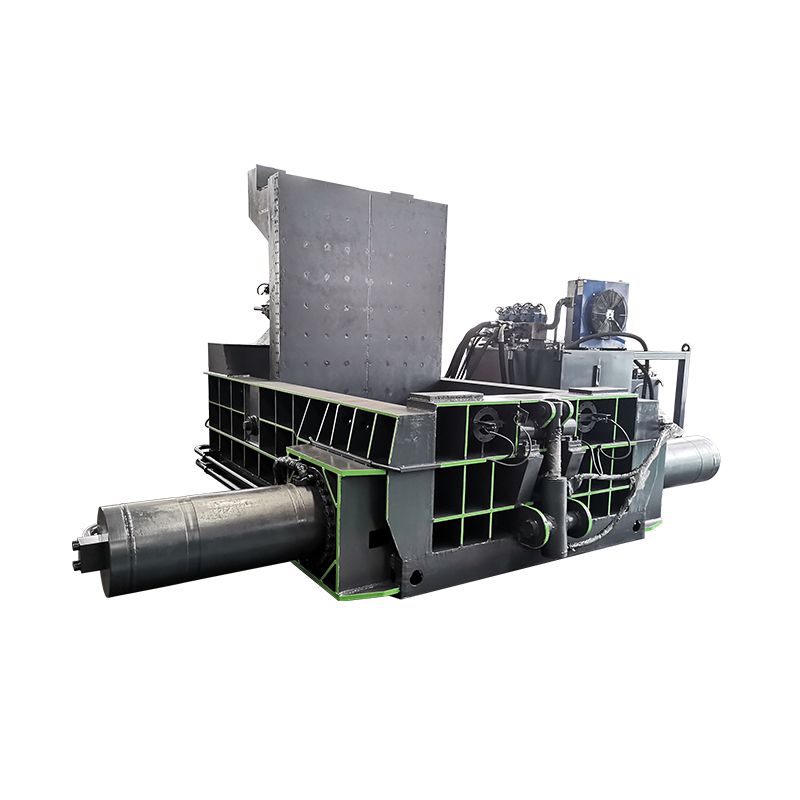

Hydraulic Scrap Copper Metal Baler Machine For Metal Recycling Markets

Introduction

Y81 hydraulic metal balers are mostly used in waste recycling stations, steel mills, recycling and processing industries, etc. The compressible materials of Y81-250 baler include steel shavings, scrap copper, scrap aluminum, scrap stainless steel, etc. The suitable baler model can be selected according to the daily processing volume of waste and the size of the bale block. This baler adopts frequency conversion motor with adjustable speed, automatic start and stop, feeding stop, power saving and energy saving.

Technical Specification

|

1 |

Main oil cylinder |

Model |

YG340/220 |

Qty. |

2 pc |

|

Normal force |

2500 KN |

Stroke |

730 mm |

||

|

2 |

Side pressure cylinder |

Model |

YG240/160 |

Qty. |

2 pc |

|

Normal force |

1100 kN*2 |

Stroke |

2070 mm |

||

|

3 |

Turning bag cylinder |

Model |

YG240/160 |

Qty. |

1 pc |

|

Normal force |

1100 kN |

Stroke |

1900 mm |

||

|

4 |

Door cover cylinder |

Model |

YG140/75 |

Qty. |

1 pc |

|

Normal force |

120 kN |

Stroke |

320 mm |

||

|

5 |

Size of feed box |

2500*2000*1000 mm |

|||

|

6 |

Size of bale |

500*500 mm |

|||

Features

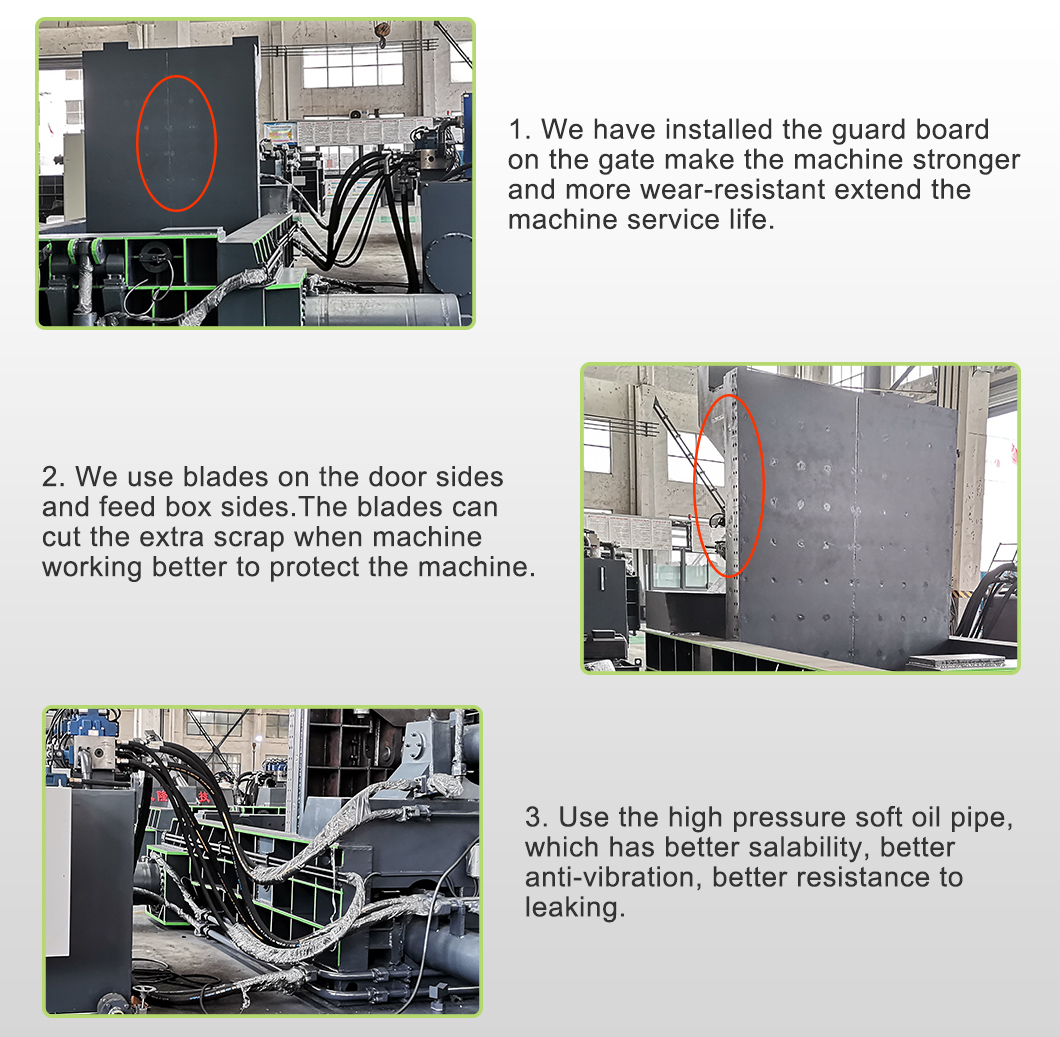

1. We have installed the guard board on the gate make the machine stronger and more wear-resistant extend the machine service life.

2. We use blades on the door sides and feed box sides.The blades can cut the extra scrap when machine working better to protect the machine.

3. Use the high pressure soft oil pipe,which has better salability, better anti-vibration, better resistance to leaking.

Main configuration of the hydraulic metal baler:

1. High pressure oil pump

2. Motor

3. Low-voltage electrical component

4. Limit switch

5. Cylinder seal

6. Electro-hydraulic valve

7. Overflow valve

Workshop

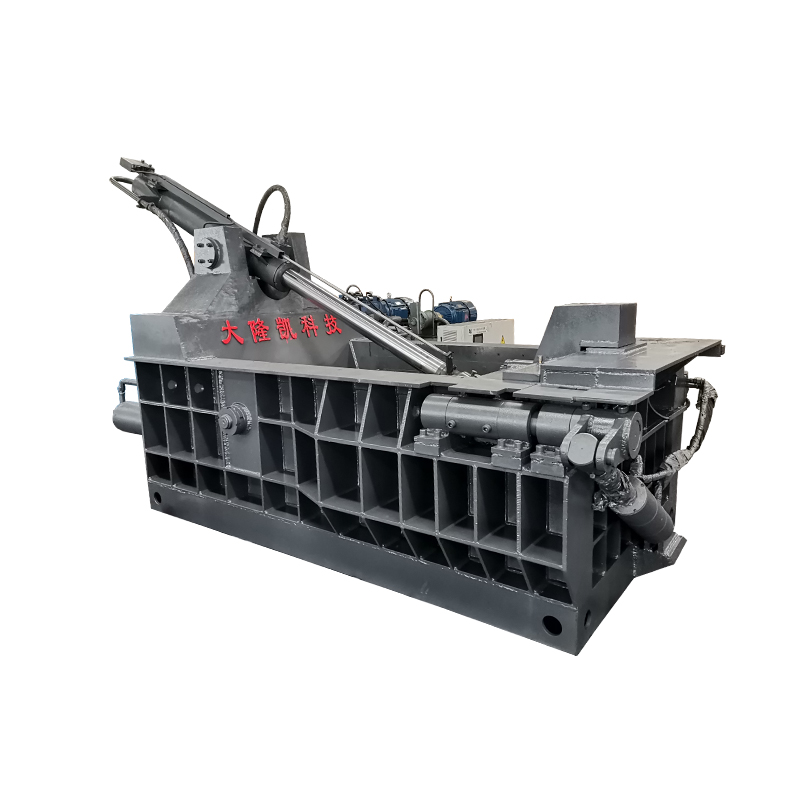

Related Products

Are there any products you like?

24 hours a day online service, let you satisfaction is our pursuit.