Product Description

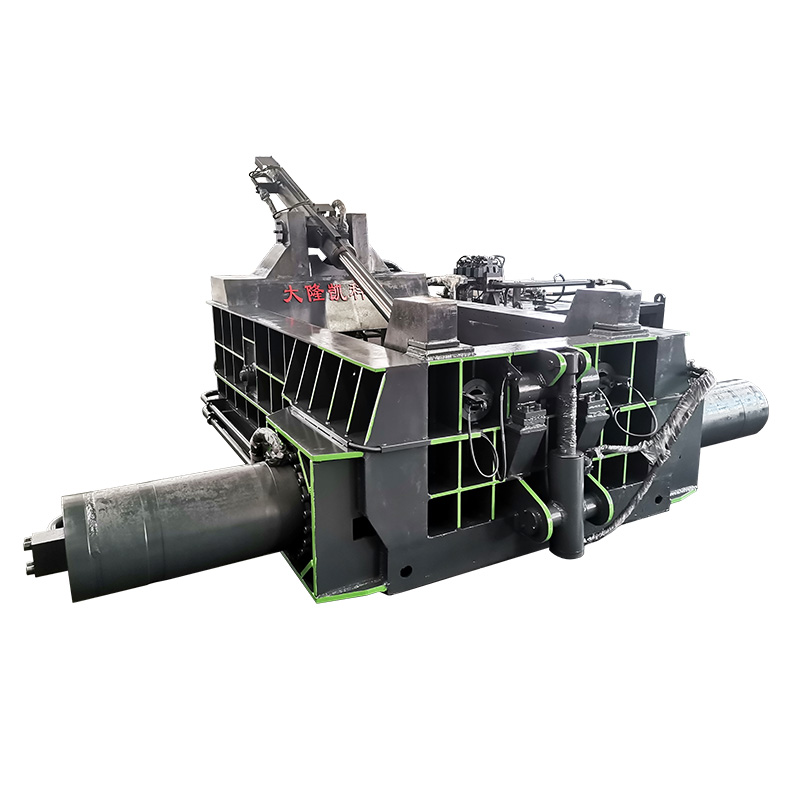

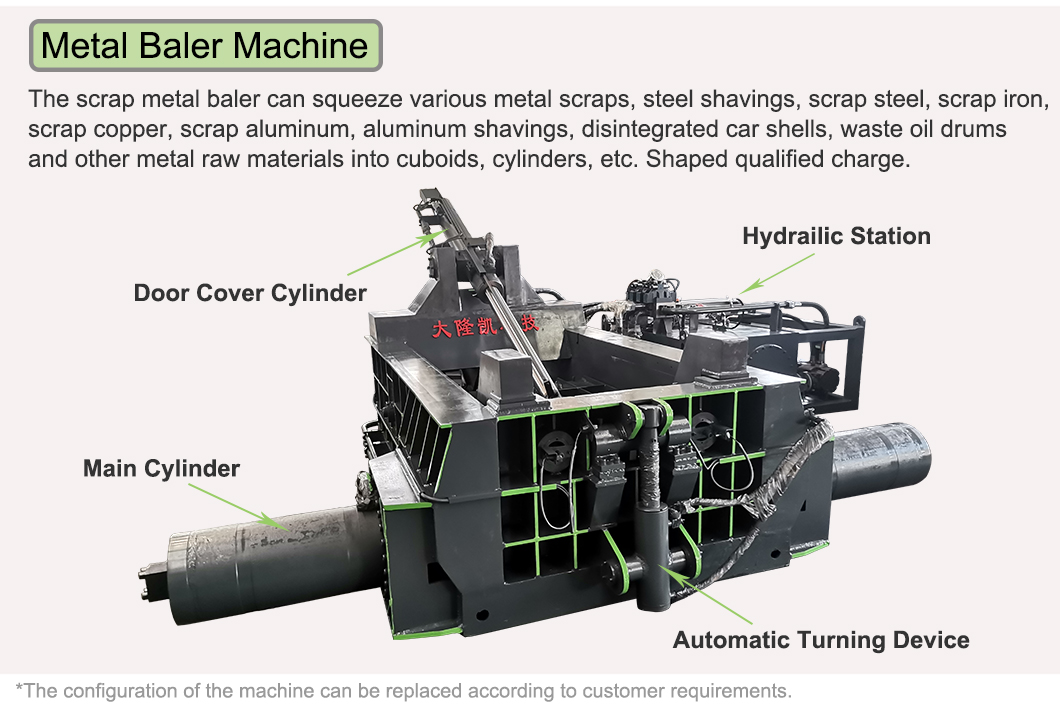

Y81 series balers can be used in scrap metal recycling stations to pack and compress scrap metal scraps. The packaging materials include steel shavings, scrap steel, scrap copper, scrap iron, scrap steel bars, scrap stainless steel, waste oil drums, etc. This fully automatic front-turning baler with a master cylinder pressure of 200 tons is mostly used in small waste recycling stations. The production rate of this baler is approximately 7-15 bales per hour. The bale is 300mm octagonal, and the size of the bale can also be customized if the customer needs. This metal baler can be powered by a diesel engine in places where there is no power supply. In recent years, our hydraulic scrap metal balers have been widely used in the scrap metal recycling industry.

Technical Parameters

|

No. |

Parameter name and content |

|

|

1 |

Model | Y81QF-200 |

|

2 |

Main Cyl.Force | 2000 KN |

|

3 |

Hydraulic system working pressure | ≤26MPa |

|

4 |

Tank (compression chamber) specifications | 1800*1400*800 mm |

|

5 |

Block section size*minimum length | (600*600)*600 mm |

|

6 |

Operation method | Hand-in-one, remote control operation |

|

7 |

Productivity | About 7-15 bags/hour |

|

8 |

Outlet method | Forward turning-out |

|

9 |

Power Specifications | 380 V/3P |

|

10 |

Total equipment power | 62.05 KW |

Application

The horizontal metal scraps baler is suitable for various large, medium and small factories, waste metal recycling processing industry and non-ferrous metal smelting industry.

The used metal baler machine can press various metal scraps, steel shavings, scrap steel, scrap aluminum, scrap copper, etc. into qualified shapes such as cubes, cylinders, octagons, etc. to reduce the transportation and smelting costs of metal scraps materials.

Related Products

Are there any products you like?

24 hours a day online service, let you satisfaction is our pursuit.